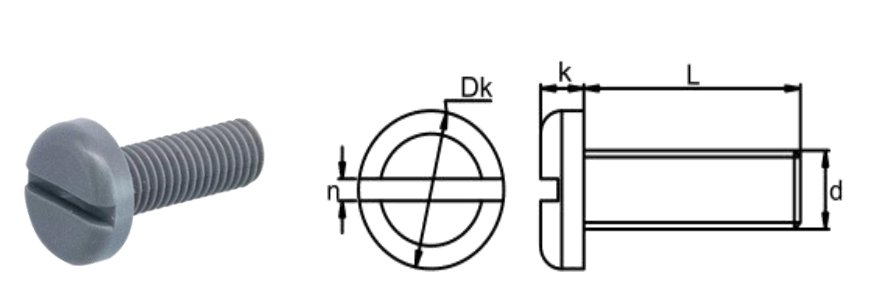

CPVC Slotted pan head screw

CPVC Slotted pan head screw material is heat resistant, resistant to corrosion from acids, alkalis, salts, oxidants, etc. The maximum continuous use temperature can reach 90-100°C

M Size: M3-M8

peek plastic material: chlorinatedpolyvinylchloride (CPVC)

product type: Pan head bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

CPVC Slotted pan head screw Overview

CPVC (Chlorinated Polyvinyl Chloride) Slotted Pan Head Screw is a type of plastic screw utilized in applications requiring chemical resistance, high temperature tolerance (relative to standard PVC), and electrical insulation. The specific Pan Head design offers a large bearing surface for strong clamping, while the Slotted Drive allows for simple installation.

| Feature | Detail | Purpose |

| Material | CPVC (Chlorinated Polyvinyl Chloride) | Provides excellent chemical resistance, especially to acids, alkalis, and automotive fluids, at temperatures higher than standard PVC. |

| Head Style | Pan Head |

Product Parameters

CPVC Pan Head Screws typically follow standards such as ISO 7045 (Cross Recessed Pan Head) or equivalents for the slotted drive.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (Approx.) |

| M3 | 0.5 mm | 6.0 mm | 2.4 mm | 0.8 mm |

| M4 | 0.7 mm | 8.0 mm | 3.1 mm | 1.0 mm |

| M5 | 0.8 mm | 9.5 mm | 3.7 mm | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 4.4 mm | 1.6 mm |

Key Features

CPVC screws are chosen primarily for their environmental resistance profile:

Chemical Resistance: Excellent stability against most mineral acids, bases, and salts.

Thermal Tolerance: Better heat resistance than standard PVC, allowing for service temperatures higher than 90°C.

Electrical Insulation: Inherently non-conductive, offering good dielectric properties.

Cost-Effectiveness: More expensive than PVC but generally much more economical than high-performance polymers like PFA or PEEK.

Applications

- Automotive parts: engine covers, fans, gears

- Mechanical parts: bearings, gears, pulleys.

- Electronic and electronic components: switches, terminal blocks.

- Consumer goods: tool handles, sports equipment.

Advantages and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Excellent corrosion resistance in contact with common chemicals; Good high-temperature rating for a vinyl polymer. | Low Mechanical Strength: Cannot withstand high loads or installation torque; Prone to creep under pressure. |

| Design | Pan head maximizes surface contact for good clamping; Cost-effective chemical resistance. | Slotted drive is prone to cam-out (slipping) and offers lower torque control compared to Phillips or socket drives. |

| Material | Lightweight, non-contaminating, and non-magnetic. | Poor UV resistance; Can be brittle in very cold temperatures. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.