PA66 Hexagon socket head screw

PA66 Hexagon socket head screw describes a fastener that combines the properties of PA66 material with a hexagonal drive design.

M Size: M3-M12

peek plastic material: Polyamide66(PA66)

product type: Hexagon socket head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66 Hexagon socket head screw Overview

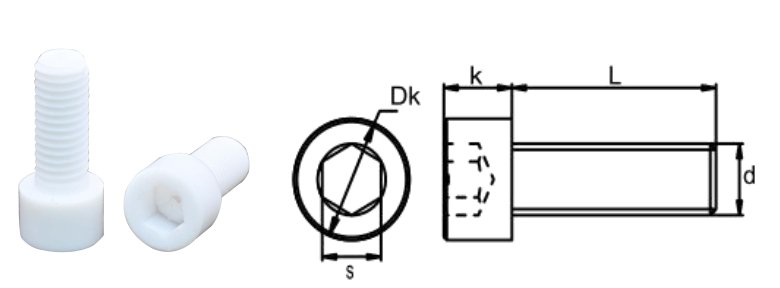

PA66 Hexagon Socket Head Screw (PA66 Socket Head Screw) is a fastener that combines the material properties of PA66 with the engineering benefits of the Hex Socket drive design. It is characterized by its cylindrical head and internal hexagonal drive, utilizing an Allen Key/Hex Key for installation, making it ideal for applications requiring flush mounting and compact space.

Key Features

The core value of the PA66 Socket Head Screw lies in the synergy between its material and structure:

- Electrical Insulation (PA66 Electrical Insulation Bolt): PA66 material offers excellent insulation, making it the perfect choice for electronic and electrical equipment where isolation or short-circuit prevention is necessary.

- Corrosion Resistance: PA66 exhibits superb chemical corrosion resistance (PA66 Corrosion Resistant Screw), capable of withstanding fuels, oils, weak alkalis, and many solvents. Crucially, it never rusts, making it highly suitable for humid, marine, or chemical environments.

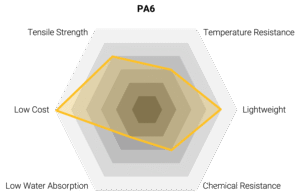

- Mechanical Properties and Lightweighting: Standard PA66 possesses good strength and stiffness. Its extremely low density translates into a significant lightweight advantage (PA66 Screw Lightweight Advantage), helping to reduce overall assembly weight.

- Space Efficiency and High Torque (Hex Socket Design): The Hex Socket drive design allows the screw head to be flush or slightly protruded with the fastened surface, saving external space. Compared to traditional slot or Phillips drives, the hex socket can withstand a higher installation torque.

- Thermal Stability: PA66 has a relatively high melting point and continuous service temperature (relevant to searches for PA66 High Temperature Screw), maintaining stability within a certain temperature range.

Key Polyamide Nylon (PA6) Properties

Comprehensive Analysis of Pros and Cons

✅ Advantages (Pros)

- Insulation and Safety: Provides electrical insulation, eliminates short-circuit risks, and is non-heat conductive.

- Corrosion Proof: Never rusts in any humid or chemical environment.

- Space Efficiency: Hex Socket design enables flush or compact installation (Hex Socket Tight Space Installation).

- Lightweight: Contributes significantly to weight reduction goals (PA66 Screw Lightweight Advantage).

- Damping: The polymer material aids in PA66 Vibration Damping Screw applications.

❌ Disadvantages (Cons)

- Strength Limitations: Compared to metal, its load-bearing capacity and shear strength are lower (Nylon Screw Strength Limitations).

- Torque Risk: Although the hex socket design increases torque capability, the nylon material necessitates strict control over installation torque (Plastic Screw Torque Specs). Overtightening can easily lead to thread stripping or head breakage (PA66 Screw Stripping Risk).

- Moisture Impact: PA66 exhibits some moisture absorption (PA66 Moisture Absorption). In long-term use in humid environments, its dimensions and mechanical properties may undergo slight changes.

- Creep Tendency: Under long-term sustained loads, the plastic material is more prone to creep (permanent deformation) than metal.

Applications

Applications for PA66 Socket Head Screws are concentrated in fields demanding compact design, insulation, and corrosion resistance:

- Electronics and Electrical Equipment: They are the backbone of PA66 Electronic Fasteners, used to secure circuit boards, sensors, and power module casings, leveraging their insulation and non-magnetic properties.

- Automotive Industry: Widely applied in interior trim, wire harness fixation, sensor mounting, and specific non-structural components in Electric Vehicles (EVs) (PA66 Automotive Fasteners, PA66 EV Fasteners), where lightweighting and non-conductivity are required.

- Medical and Instrumentation: Suitable for precision equipment requiring non-magnetic properties, resistance to disinfectants, and a smooth, flush surface finish.

- General Machinery: Used in constrained spaces where the anti-corrosion function of the PA66 Corrosion Resistant Screw is emphasized.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.