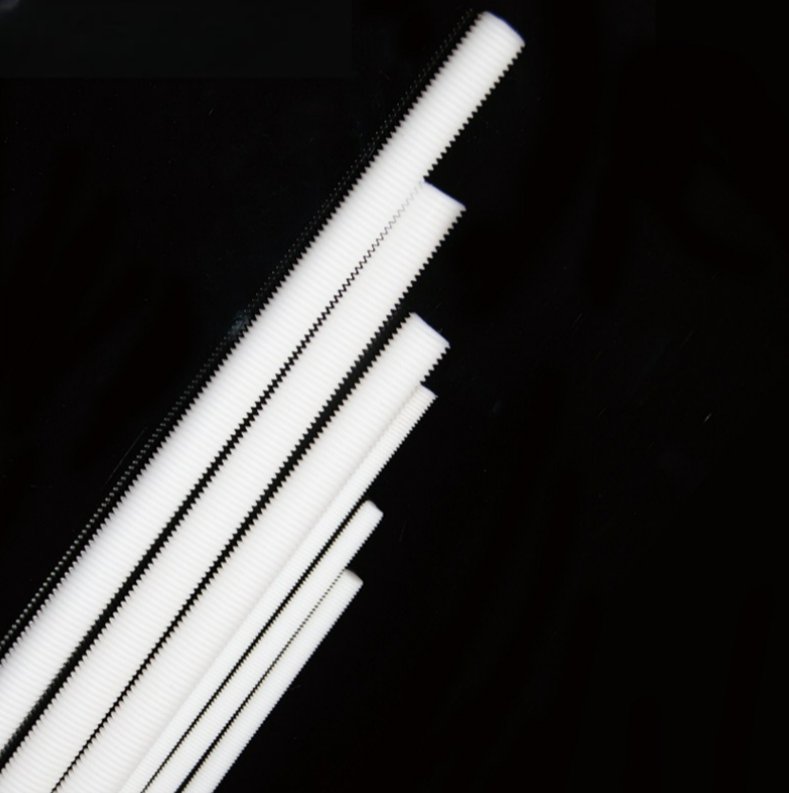

PA66+GF/Nylon fiberglass thread rod

PA66+GF/Nylon fiberglass thread rod offers high mechanical strength and heat resistance.

M Size: M6-M16

peek plastic material: pp/PA66+GF/PTFE/PEEK

COLOR:Naturalcolor/pink/blue/orange.Othercolorscanbe Customizable

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PA66+GF/Nylon fiberglass thread rod Overview

PA66+GF/Nylon fiberglass thread rod

PA66+GF threaded rods—often described as threaded rod, thread rod, threaded rods, rod thread, all thread rod, or plastic threaded rod—are high-strength fasteners manufactured from glass-fiber reinforced Nylon 66. By integrating a high percentage of glass fiber (typically 25–50%), PA66+GF significantly improves stiffness, tensile strength, and thermal performance compared with standard nylon threaded components.

PTFE/polytetrafluoroethylene thread rod

PTFE threaded rod—sometimes categorized under plastic threaded rod or specialty threaded rods—is a fully threaded fastener made from PTFE (polytetrafluoroethylene). PTFE is known for its exceptional chemical resistance, non-stick surface, excellent dielectric properties, and high temperature resistance.

PA66+GF/Nylon fiberglass thread rod Design

The design is a simple, straight all thread rod featuring external threads along its entire length.

Thread Profile: Usually follows standard metric threaded rod (ISO) or unified national coarse (UNC) thread forms to ensure compatibility with standard nuts and washers.

Reinforcement: The glass fiber content (typically 10% to 30%, often denoted as PA66-GF30) is dispersed within the Nylon matrix. This reinforcement is crucial for achieving strength comparable to some low-carbon ss all thread rod options.

Alternatives: These are used in applications where a metal threaded rod anchor or an internally threaded rod solution is overkill or unsuitable.

Product Parameters

PA66 + GF all thread rod is manufactured by extrusion or injection molding, creating a continuous rod with external rod thread. The addition of glass fiber significantly enhances the mechanical properties of the base Nylon 66 polymer.

| Metric Size | Imperial Equivalent | Outer Diameter (mm) | Thread Pitch (mm) |

| M4 | 1/8″ (Approx.) | 4.0 | 0.7 |

| M6 thread rod | 1/4 all thread rod (Approx.) | 6.0 | 1.0 |

| M8 | 5/16″ (Approx.) | 8.0 | 1.25 |

| M10 | 3/8 threaded rod / threaded rod 3/8 | 10.0 | 1.5 |

| M12 | 1/2 all thread rod (Approx.) | 12.0 | 1.75 |

| M16 | 5/8″ (Approx.) | 16.0 | 2.0 |

| M20 | 3/4 all thread rod (Approx.) | 20.0 | 2.5 |

Key Features

The inclusion of glass fibers fundamentally upgrades the base PA66 material:

| Feature | Description |

| Mechanical Strength | Significantly higher tensile strength and stiffness than pure Nylon. |

| Density | Extremely lightweight, typically about 1/5 the weight of stainless threaded rod. |

| Chemical Resistance | Excellent resistance to organic solvents, oils, and fuels. |

| Electrical Properties | Excellent electrical insulator; essential for non-conductive applications. |

| Corrosion Resistance | Completely immune to rust and galvanic corrosion. |

| Temperature Range | Good thermal stability, with a relatively high continuous operating temperature (up 100°C to 120°C ). |

Advantages VS Disadvantages

✅ Advantages (Pros)

Corrosion-Proof: Unlike carbon steel or even stainless steel all thread rod, they will never rust.

Dielectric: Provides electrical and thermal insulation.

Lightweight: Eases installation and reduces overall assembly weight.

Non-Magnetic: Ideal for MRI equipment or sensitive electronic components.

❌ Disadvantages (Cons)

Lower Tensile Strength: Despite the glass fiber, their ultimate load-bearing capacity is still lower than high-grade all thread rods made of metal.

Creep: Under continuous high static load, the material can slowly deform over time (creep), especially at elevated temperatures.

Moisture Absorption: Nylon can absorb moisture, which can slightly affect its dimensional stability and mechanical properties.

UV Degradation: Standard PA66 can degrade if exposed to prolonged, direct UV light, though UV-stabilized versions are available.

Applications

PA66 + GF threaded rods are ideal for environments where metal rods pose a risk or have insufficient performance.

Corrosive Environments: Chemical processing plants, maritime applications, and water treatment facilities where metal corrodes rapidly.

Electrical Insulation: Used as tie-rods or supports in electronic cabinets, antennas, and high-voltage equipment where electrical isolation is mandatory.

Lightweighting: Aerospace interiors, drones, and other applications requiring maximum weight reduction.

Clean Rooms/Medical: Applications requiring non-contaminating, non-magnetic, and chemically inert fasteners.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.