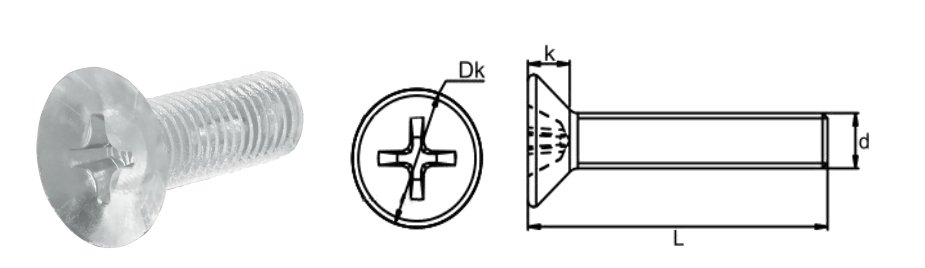

PC Cross countersunk head screw

PC Cross countersunk head screw has strong impact resistance, strong fatigue resistance, good heat aging resistance, excellent insulation performance, resistance to weak acids and weak alkalis; and is self-extinguishing.

M Size: M2-M12

peek plastic material: PC Polycarbonate

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PC Cross countersunk head screw Overview

PC (Polycarbonate) Cross Countersunk Head Screws are high-strength plastic screws engineered for lightweight structural fastening, optical clarity, electrical insulation, and excellent impact resistance. Their countersunk head design allows the screw to sit flush with the mounting surface—similar to metal countersunk bolts, countersunk head bolts, or phillips head bolts but with the advantages of polycarbonate’s toughness and transparency.

Product Parameters

PC countersunk bolts are manufactured in standard metric and imperial sizes to ensure compatibility with traditional hardware and common industry applications. Common sizes include countersunk m4 bolts for electronics and larger options like the 3 8 countersunk bolt for general assembly.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) | Key Application Area |

| M3 | #4 | 6.0 mm / 0.24 in | Circuit boards, Small covers |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in | Electrical panels, Instrumentation |

| M6 | 1/4″ | 12.0 mm / 0.47 in | Security panels, Display mounts |

| M10 | 3/8″ (3 8 countersunk bolt) | 18.0 mm / 0.71 in | Heavy lighting fixtures, Machine guards |

Key Features

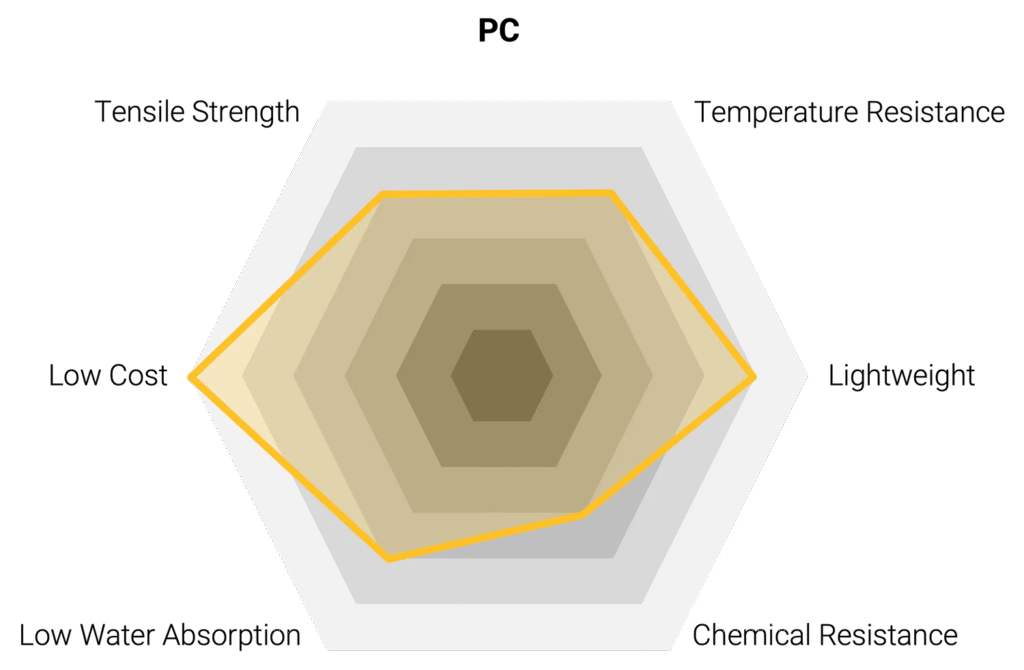

Polycarbonate screws offer a unique combination of strength and optical properties, making them suitable for applications where material visibility or toughness is required.

High Impact Resistance: PC is exceptionally tough, providing resistance to shattering and impact loading far superior to Nylon or acrylic plastic screws.

Optical Clarity: PC is inherently transparent, making it ideal for use in light-sensitive or visible assemblies.

Good Dielectric Strength: Excellent electrical insulation properties, providing safety in electronic applications.

Dimensional Stability: Maintains size and shape well across varying temperatures and humidity levels.

Good Strength-to-Weight Ratio: Offers decent mechanical strength while remaining significantly lighter than a metal bolt.

Key Polycarbonate (PC) Properties

Advantages and Disadvantages (Pros and Cons)

The choice of PC involves balancing its excellent toughness and clarity against its weaknesses in chemical and temperature resistance.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Mechanical Performance | Extremely High Impact Strength: Highly resistant to shattering. Lightweight. | Lower Wear Resistance: Softer surface is prone to scratching compared to countersunk stainless bolts. |

| Environmental Performance | Optical Clarity/Transparency. Good Electrical Insulation. | Poor Chemical Resistance: Sensitive to specific solvents (like acetone) and aromatic hydrocarbons. |

| Temperature Limits | Good (better than Nylon), but lower than high-performance plastics like PEEK. | UV Sensitivity: Can yellow and degrade over long-term outdoor UV exposure unless stabilized. |

| Installation | Compatible with standard Phillips head bolts tools; often replaces metal screws in non-structural applications. | Stress Cracking: Can be susceptible to stress cracking when installed near certain chemical solvents. |

Applications

PC screws are typically used in scenarios where toughness, clarity, and electrical isolation are crucial, but extreme heat or chemical resistance is not the primary requirement.

Electronics and Enclosures: Securing clear access panels, display screens, and PCB assemblies where transparency and insulation are needed.

Safety and Security: Fastening protective shields, machine guards, or safety barriers due to its high impact resistance.

Lighting Fixtures: Used to assemble LED panels and transparent lighting components where a non-conductive, clear fastener is required.

General Assembly: A superior alternative to common Nylon when higher impact strength is required.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.