PEEK Countersunk Hexagon Socket Screws

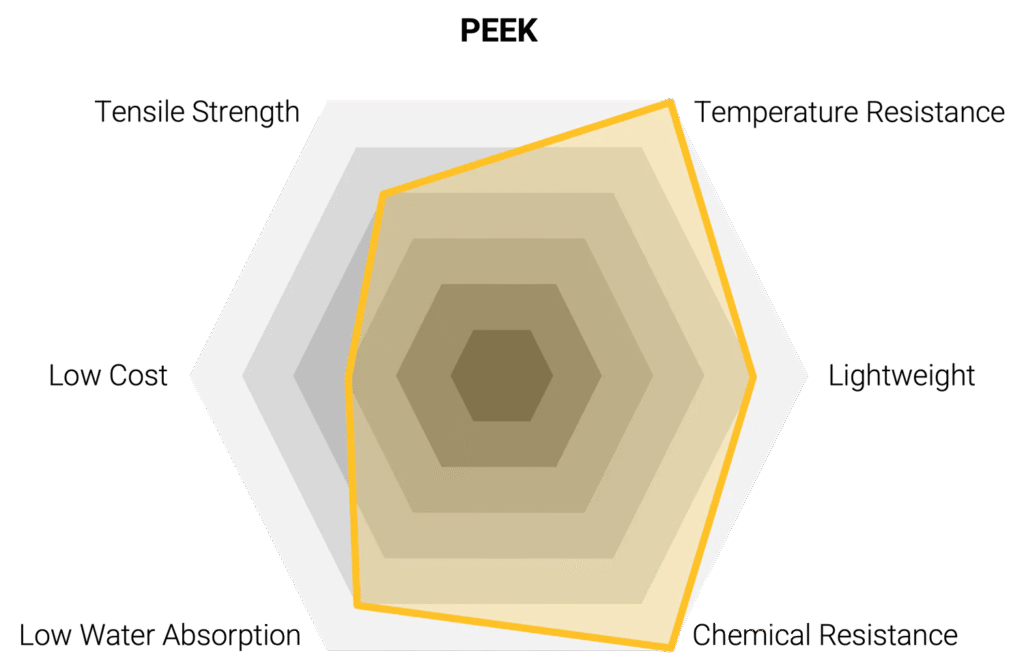

PEEK Countersunk Hexagon Socket Screws are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M2.5-M16

peek plastic material: Polyetheretherketone (PEEK)

Thread Type: Hexagonal bolts

Length Range: 15mm-200mm (Customizable)

Finish: Natural/Black/Other Colors

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Countersunk Hexagon Socket Screws Overview

PEEK Countersunk Hexagon Socket Screw is a highly specialized fastener that combines the superior chemical and thermal resistance of PEEK (Polyether Ether Ketone) with a geometry designed for high-torque, flush installation. It is utilized in critical industrial applications that demand a fastener that is non-corrosive, lightweight, and capable of maintaining a sleek surface finish under extreme environmental conditions.

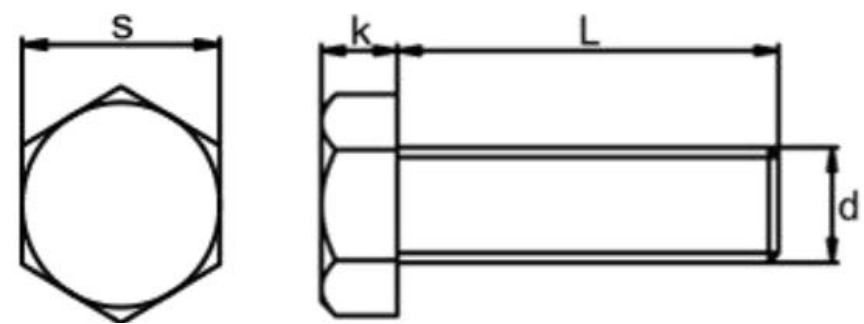

Product Parameters

PEEK Countersunk Hexagon Socket Screws typically adhere to the dimensional standards of ISO 10642 (or equivalent DIN 7991).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Angle (α) | Socket Size (s) |

| M3 | 0.5 mm | 6.0 mm | 90°C | 2.0 mm |

| M4 | 0.7 mm | 8.0 mm | 90°C | 2.5 mm |

| M5 | 0.8 mm | 9.5 mm | 90°C | 3.0 mm |

| M6 | 1.0 mm | 11.0 mm | 90°C | 4.0 mm |

| M8 | 1.25 mm | 14.0 mm | 90°C | 5.0 mm |

| M10 | 1.5 mm | 16.0 mm | 90°C | 6.0 mm |

| M12 | 1.75 mm | 18.0 mm | 90°C | 8.0 mm |

Key Features

PEEK Countersunk Hexagon Socket Screws are chosen when the application requires a fastener to excel in multiple extreme categories simultaneously:

Extreme Thermal Stability: Maintains structural integrity up to 260°C (500°C), making it suitable for high-heat industrial processes.

Superior Mechanical Strength: Offers the highest strength-to-weight ratio among polymer fasteners, with excellent creep resistance.

Chemical Inertness: Resistant to virtually all common solvents, acids, and bases, ensuring zero corrosion.

Flush Installation: The countersunk head provides an aerodynamic, snag-free, and cleanable surface finish.

Non-Conductive & Non-Magnetic: Essential for electrical isolation and use in sensitive medical or analytical instrumentation.

Applications

These screws are vital in high-tech and specialized environments where failure is costly or catastrophic:

Semiconductor Manufacturing: Securing cleanroom and wet-bench components where purity and chemical resistance are absolute requirements.

Aerospace: Used for internal paneling and assemblies, where the flush profile, lightweight nature, and high strength are critical.

High-Temperature Equipment: Fastening components in industrial ovens, sterilizers (autoclaves), and high-heat processing machinery.

Medical/Pharmaceutical: Employed in non-magnetic instruments and fluid systems requiring high heat resistance for sterilization.

Advantages

The decision to use PEEK Countersunk Hexagon Socket Screws is a premium choice, trading the ultimate load capacity of steel for unmatched environmental performance.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Extreme Thermal & Chemical Resistance. Corrosion and Galling Immunity. Flush Design for clean surfaces. | Highest Cost: Significantly more expensive than any other common plastic or steel fastener. |

| Mechanical | Highest Polymer Strength and best resistance to creep under load. High Torque Drive (Hex Socket). | Lower Ultimate Load Capacity: Cannot match the absolute tensile strength of high-grade steel screws. |

| Installation | Wrench-driven (Hex Socket) allows for maximum controlled polymer torque. | Requires very precise hole preparation (countersinking) and strict torque control to avoid stripping the thread. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.