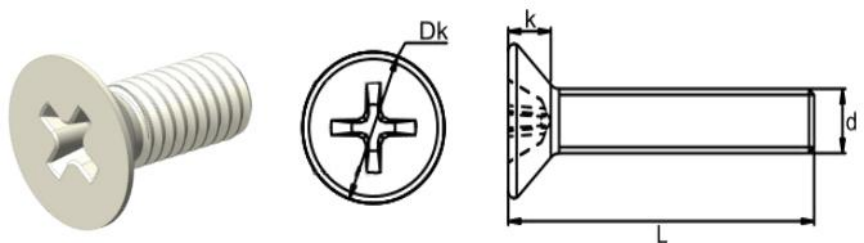

PEEK Cross pan head bolts

PEEK Cross pan head bolts are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M2-M10

peek plastic material: Polyetheretherketone (PEEK)

Thread Type:Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Cross pan head bolt Overview

PEEK Cross Pan Head Bolts—sometimes searched as PEEK cross pan head, PEEK pan head bolt/screw, pan cross head screw, cross pan head screw, pan cross head, pan head screw, or screw pan head—are high-performance fasteners manufactured from polyetheretherketone (PEEK), an advanced engineering thermoplastic known for exceptional mechanical and chemical resistance.

PEEK cross pan head screw is chosen specifically to solve environmental challenges (heat, corrosion) where traditional stainless steel pan head screws would fail due to conductivity, magnetism, or excessive heat transfer.

I. Overview and Design

| Feature | Detail | Purpose |

| Material | PEEK (Polyether Ether Ketone). A high-performance thermoplastic polymer. | Provides extreme temperature, chemical, and mechanical resistance in a lightweight, non-metallic component. |

| Head Style | Pan Head. Characterized by a slightly rounded top and large, flat bearing surface beneath. | Offers excellent pull-through resistance for the PEEK material, making it ideal for securing thin panels and covers. |

Product Parameters

These screws adhere to established metric standards for cross-recess pan head screws, such as ISO 7045 (or equivalents like DIN 7985), ensuring compatibility with standard tools and thread systems.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Cross Recess Size (PH) |

| M3 | 0.5 mm | 6.0 mm | 2.4 mm | PH1 |

| M4 | 0.7 mm | 8.0 mm | 3.1 mm | PH2 |

| M5 | 0.8 mm | 9.5 mm | 3.7 mm | PH2 |

| M6 | 1.0 mm | 10.5 mm | 4.2 mm | PH3 |

| M8 | 1.25 mm | 14.0 mm | 5.3 mm | PH3 |

| M10 | 1.5 mm | 17.0 mm | 6.5 mm | PH4 |

Key Features

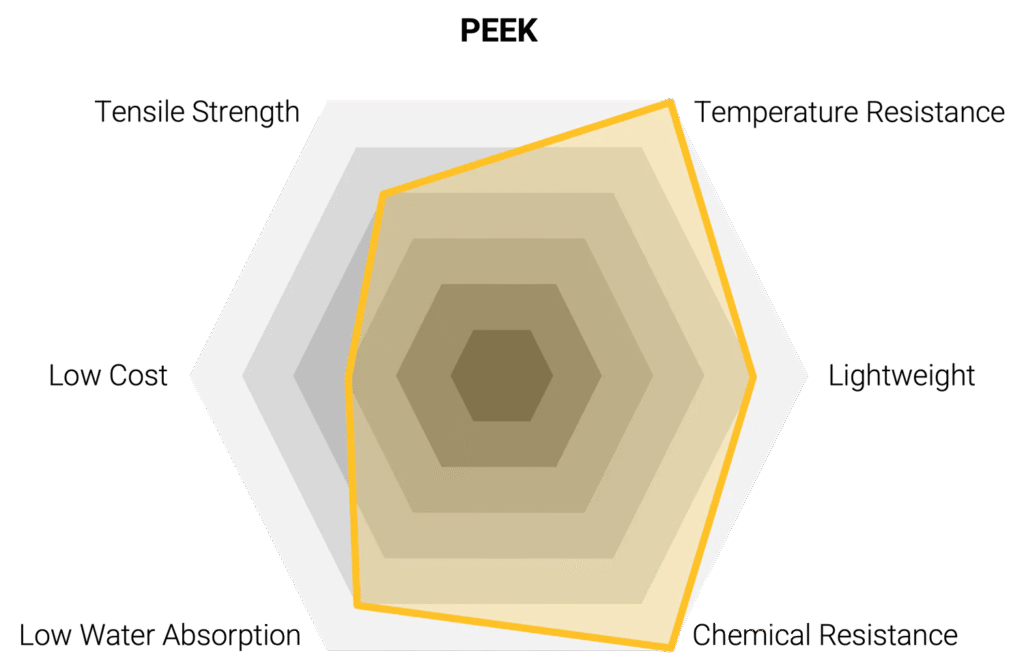

PEEK’s unique molecular structure grants the fastener unparalleled properties among polymers:

- Extreme Thermal Resistance: PEEK has the highest continuous service temperature (up to 260°C) of all standard engineering plastics, making it a reliable PEEK High Temperature Fasteners solution, significantly higher than PA66.

- Exceptional Chemical Resistance: PEEK is highly inert and resistant to almost all common organic and inorganic chemicals, including strong acids, bases, and solvents, reflected in searches for PEEK Chemical Resistant Bolts.

- High Mechanical Integrity: It offers excellent tensile strength, stiffness, and hardness, competing with aluminum and stainless steel in some respects, classifying it as a PEEK Non-Metallic High Strength fastener.

- Corrosion Immunity and Electrical Insulation: PEEK is completely corrosion-proof, non-magnetic, and maintains excellent dielectric properties even at high temperatures.

- Creep and Radiation Resistance: PEEK exhibits outstanding resistance to creep (permanent deformation under load) and high stability against nuclear radiation.

Key Polyether Ether Ketone (PEEK) Properties

Usage Scenarios, Advantages, and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Extreme heat and chemical resistance while being lightweight and non-magnetic. Superior creep resistance over PTFE. | High Cost: PEEK is one of the most expensive fasteners. | Semiconductor: Securing access panels in plasma etching and cleanroom equipment. |

| Design | Pan-Head offers excellent clamp-load distribution for a polymer screw. Cross drive allows for rapid assembly. | Torque Limitation: Must be installed with limited, controlled torque to prevent drive recess stripping or thread damage. | Medical Devices: Fastening components that require high-purity and repeated steam sterilization (autoclave). |

| Material | Maintains structural integrity at high temperatures. Resistant to steam and hydrolysis. | Lower Strength than Metal: Cannot sustain the high tensile loads of stainless steel pan head screws (e.g., stainless pan head screws). | Aerospace/Automotive: Lightweight electrical components or brackets near heat sources. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.