PEEK Hexagon head bolt

PEEK Hexagon head bolt are a semi-crystalline plastic. 30% carbon fiber filled PEEK bolts offer excellent chemical resistance and are widely used in applications ranging from consumer electronics to chemical manufacturing.

M Size: M3-M16

peek plastic material: Polyetheretherketone (PEEK)

Thread Type: Hexagonal bolts

Length Range: 15mm-200mm (Customizable)

Finish: Natural/Black/Other Colors

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Hexagon Head Bolts Overview

PEEK Hexagon Head Bolts—commonly referred to as hex bolt, hex bolts, hex head bolt, hex head bolts, hex bolt screw, hex headed bolt, bolt hex head, or hex screw bolt—are precision fasteners made from Polyetheretherketone (PEEK), a high-performance engineering polymer known for exceptional thermal stability, strength, and chemical resistance.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PEEK) | Polyether Ether Ketone. A high-performance thermoplastic polymer. | Provides exceptional thermal, chemical, and mechanical stability in a lightweight, non-metallic form. |

| Head Style | Hexagon Head (Six-sided). Often referred to as a hex-headed bolt or hex head bolts. | Allows for external wrench tightening, enabling the maximum controlled clamping force and torque application achievable with PEEK material. |

| Drive System | External Hexagonal drive. | Uses standard tools (wrenches or sockets), unlike an internal hex bolt (socket head). |

| Standards | Typically conforms to metric standards like ISO 4017 (fully threaded) or ISO 4014 (partially threaded). | Ensures dimensional interchangeability with standard hex bolts and nuts (e.g., hex bolt nut) and tapped holes. |

Product Parameters

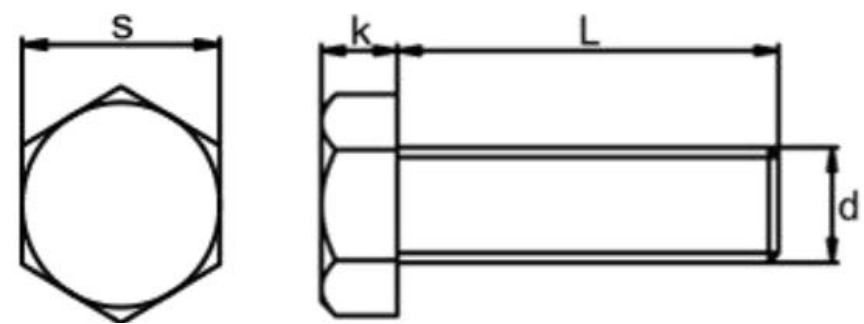

PEEK Hexagon Head Bolts adhere to established metric standards (ISO/DIN). The key dimensions include the nominal diameter (D), thread pitch (P), the width across flats (s), and the head height (k). These dimensions are essential for compatibility with hex bolt sizes and hex bolt head size.

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) | Common Lengths (L) |

| M4 | 0.7 mm | 7.0 mm | 2.8 mm | 10 mm to 40 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm | 12 mm to 60 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm | 16 mm to 80 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm | 20 mm to 100 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm | 25 mm to 100 mm+ |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm | 30 mm to 150 mm |

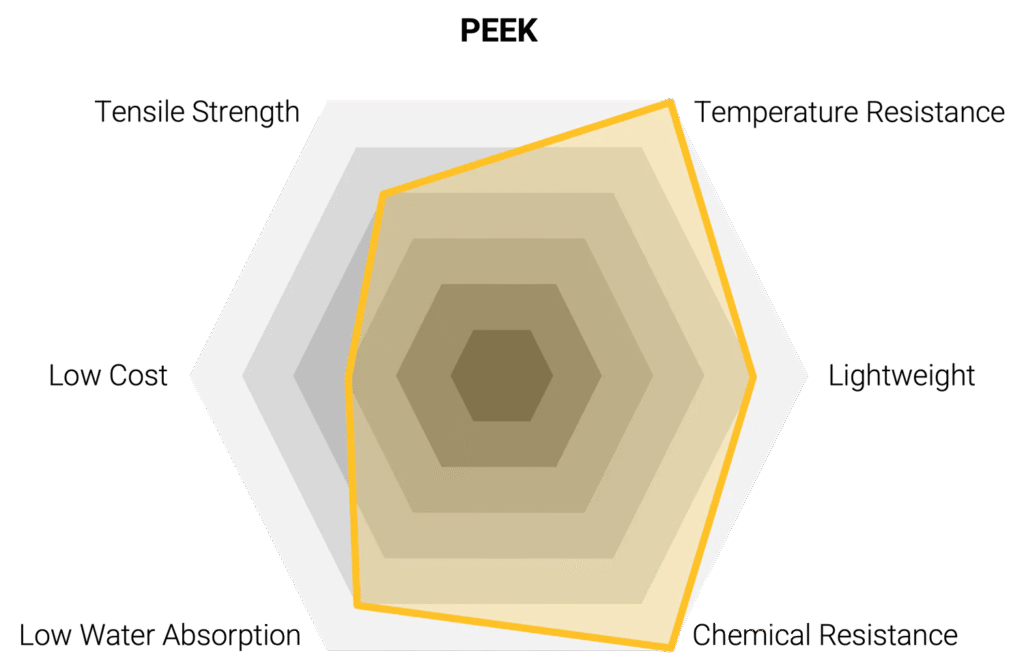

Key Features

The PEEK hex head bolt is defined by its ability to perform under severe conditions:

Extreme Thermal Stability: Continuous operating temperature up to 260°C (500°C), with high dimensional stability.

Superior Chemical Resistance: Highly inert, resisting most organic and inorganic chemicals, solvents, and fuels.

High Mechanical Strength: Excellent tensile strength, stiffness, and creep resistance (maintaining preload under sustained stress and heat).

Non-Magnetic & Non-Conductive: Ideal for use in MRI equipment, electronic devices, and high-voltage insulation, unlike stainless steel hex head bolts or black hex head bolts.

Hydrolysis Resistance: Unaffected by hot water and high-pressure steam, crucial for sterilization.

Hexagon head bolt main characteristics diagram

Usage Scenarios, Advantages, and Disadvantages

PEEK hex head bolt is specifically chosen when the structural requirements demand a material superior to PTFE, yet the environment prohibits the use of any metal, including stainless hex head bolts.

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Highest strength-to-weight ratio among high-temp thermoplastics. Exceptional resistance to fatigue and creep. | High Cost: PEEK is one of the most expensive fasteners on the market. | Oil & Gas (Downhole): Fastening components exposed to high pressure and heat (220°C). |

| Design | Hex Head allows for maximum, controlled torque application and easy disassembly with standard tools (wrench for hex bolts). | Lower Ultimate Strength: Cannot match the absolute tensile strength of metal fasteners (e.g., ss hex bolt). | Medical Implants: Structural fastening in biocompatible devices and surgical tools. |

| Environment | Complete immunity to corrosion, non-conductive, non-magnetic. | Installation Care: Requires precise torque control to avoid thread stripping, despite PEEK’s stiffness. | Chemical Processing: Structural joints and flanges in reactors and piping handling aggressive fluids. |