PEEK Hexagon Socket Screws

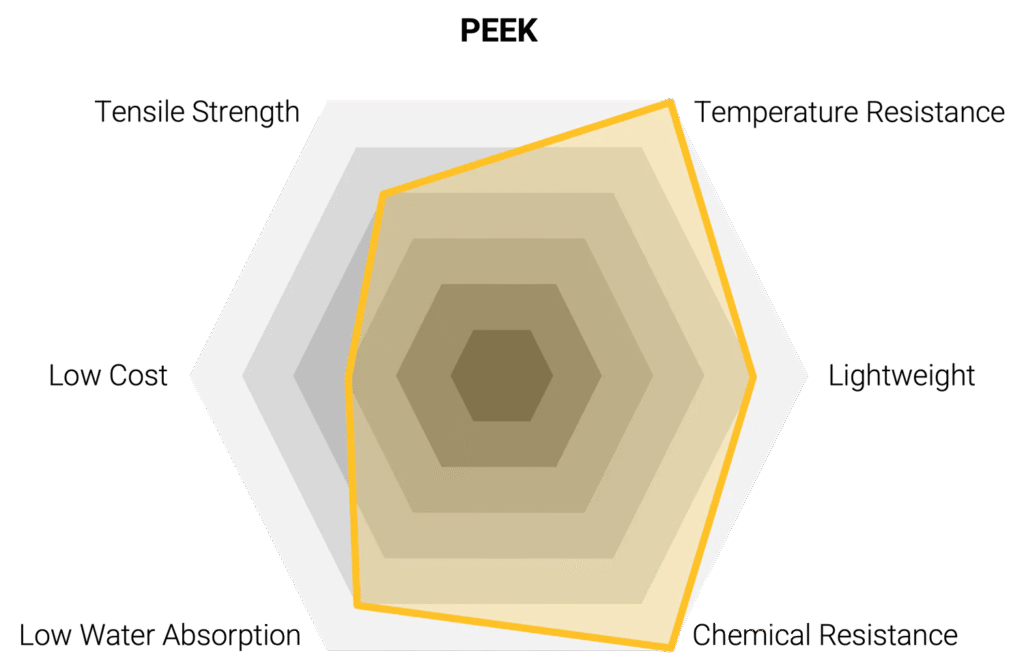

PEEK hexagon socket screws are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M2.5-M16

peek plastic material: Polyetheretherketone (PEEK)

Thread Type: Hexagonal bolts

Length Range: 15mm-200mm (Customizable)

Finish: Natural/Black/Other Colors

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK Hexagon Socket Screws Overview

PEEK Hexagon Socket Screws are high-performance fasteners manufactured from PEEK (Polyether Ether Ketone), one of the strongest and most chemically resistant engineering polymers available. Designed with a hexagon (Allen) drive recess, these screws are widely used in high-temperature, high-load, and chemically aggressive applications where metal fasteners may corrode, add unnecessary weight, or cause electrical interference.

Product Parameters

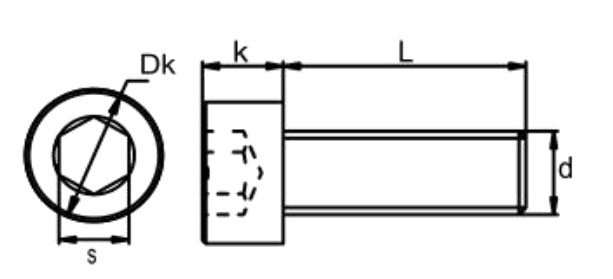

PEEK Hexagon Socket Head Cap Screws (ISO 4762 / DIN 912)

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Socket Size (S) |

| M3 | 0.5 mm | 5.5 mm | 3.0 mm | 2.5 mm |

| M4 | 0.7 mm | 7.0 mm | 4.0 mm | 3.0 mm |

| M5 | 0.8 mm | 8.5 mm | 5.0 mm | 4.0 mm |

| M6 | 1.0 mm | 10.0 mm | 6.0 mm | 5.0 mm |

| M8 | 1.25 mm | 13.0 mm | 8.0 mm | 6.0 mm |

| M10 | 1.5 mm | 16.0 mm | 10.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 12.0 mm | 10.0 mm |

Key Features

| Characteristic | Detail | Advantage over Metal/Standard Plastic |

| Mechanical Strength | Highest tensile strength, stiffness, and creep resistance of all plastic screws. | Approximates the strength of aluminum while being significantly lighter. Maintains integrity under sustained load and heat. |

| Thermal Resistance | Extreme Stability: Continuous use temperature up to $260^\circ \text{C}$ ($500^\circ \text{F}$). | Will not melt, soften, or creep in high-heat environments where Nylon or PTFE fail. |

| Chemical Resistance | Near-Universal Inertness: Excellent resistance to acids, bases, and organic solvents. | Immune to rust and galvanic corrosion, lasting longer than stainless steel in harsh chemical baths. |

| Drive System | Hexagon Socket (Allen Drive) | Allows for maximum seating torque compared to slotted or Phillips drives, ensuring a more secure, tight fastening. |

| Electrical/Magnetic | Excellent Insulator and Non-Magnetic. | Essential for electrical isolation and use in sensitive equipment like MRI machines or radar systems. |

| Purity | Ultra-High Purity: Non-leaching and non-contaminating. | Required in cleanrooms, pharmaceutical, and ultra-pure water (UPW) systems. |

Applications

PEEK Hexagon Socket Screws are utilized in mission-critical industries where their unique properties justify the high material cost:

Aerospace & Defense: Used for lightweight structures, internal components, and non-flammable assemblies.

Medical Equipment: Securing components in diagnostic instruments and sterilization equipment (autoclaves) due to bio-compatibility and heat resistance.

Semiconductor Manufacturing: Fastening parts in etching and chemical delivery systems due to supreme purity and resistance to aggressive media.

Industrial High Heat: Used in ovens, soldering equipment, and heat exchangers.

Scientific Instrumentation: Ideal for devices requiring non-magnetic, non-conductive, and chemically inert fasteners.

Advantages

- Corrosion-resistant: eliminates the problem of metal bolt rust.

- Lightweight: Weighs only 1/5 of stainless steel, reducing load.

- Insulated and anti-magnetic: Suitable for high-frequency circuits and strong magnetic field environments.

- Long life: Fatigue resistance surpasses metal, extending maintenance intervals by three times.

- Flexible customization: Supports custom sizes, colors, and performance enhancements.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.