PEEK Slotted Countersunk Bolts

PEEK slotted countersunk bolts are a kind of semi-crystalline special engineering plastic with superb performance; they have strong chemical resistance, excellent heat resistance, wear resistance, flame retardancy and hydrolysis resistance.

M Size: M2-M10

peek plastic material: Polyetheretherketone (PEEK)

Thread Type:Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PEEK slotted countersunk bolts Overview

PEEK (Polyether Ether Ketone) is a semi-crystalline thermoplastic widely regarded as the highest performance material among all plastic screws. A PEEK Cross Countersunk Head Screw is specified in critical applications where metal countersunk bolts are too heavy, conductive, or corrosive, yet the application demands extreme mechanical strength and thermal stability.

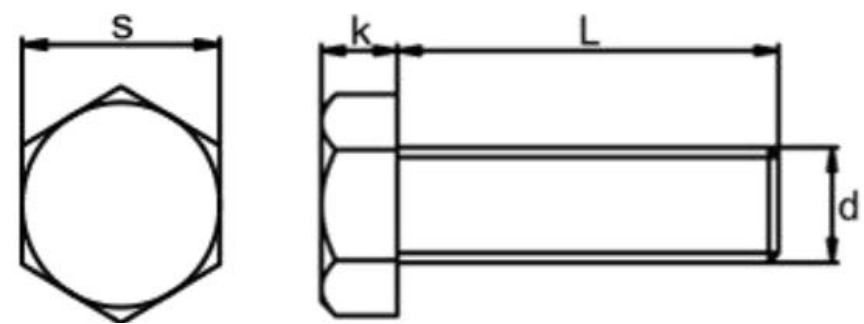

Product Parameters

PEEK countersunk bolts are manufactured to exacting tolerances, often in sizes catering to high-tech, precision industries, including common metric sizes like countersunk m4 bolts and larger imperial options like the 3 8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) | Key Application Area |

| M3 | #4 | 6.0 mm / 0.24 in | High-temp sensors, Electronics |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in | Aerospace internal panels |

| M6 | 1/4″ | 12.0 mm / 0.47 in | Industrial high-heat equipment |

| M10 | 3/8″ (3 8 countersunk bolt) | 18.0 mm / 0.71 in | Large assemblies in chemical baths |

Key Features

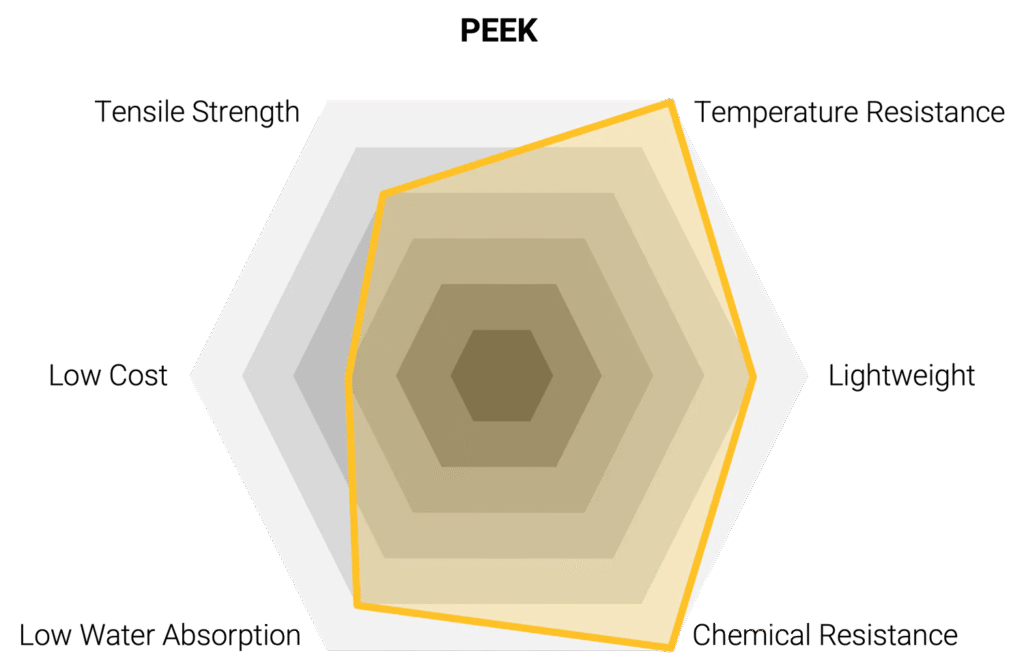

PEEK fasteners are chosen when no other polymer—or even some metals—will suffice.

Extreme Thermal Stability: PEEK offers an exceptional continuous use temperature, often exceeding 260°C (500°C), far surpassing most other plastic screws.

Superior Mechanical Strength: Possesses high tensile strength, stiffness, and fatigue resistance, making it the strongest polymer fastener available.

Excellent Chemical Resistance: Highly resistant to a vast range of organic and inorganic chemicals, including hot water and superheated steam (hydrolysis resistance).

Wear Resistance: PEEK has exceptional wear and abrasion resistance, making it suitable for friction-prone applications (e.g., bushings).

Non-Magnetic and Non-Conductive: Inherently non-magnetic and an excellent electrical insulator.

Key Polyether Ether Ketone (PEEK) Properties

Advantages and Disadvantages (Pros and Cons)

The decision to use PEEK involves prioritizing its superior performance over its cost and mechanical limits compared to metals.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Mechanical Performance | Highest Strength-to-Weight Ratio of all plastic screws. Excellent Fatigue and Wear Resistance. | Highest Cost: Significantly more expensive than any other plastic and many grades of stainless steel bolt. |

| Environmental Performance | Extreme Temperature Range and Near-Universal Chemical Resistance. Non-Conductive and Non-Magnetic. | Lower Structural Load: Cannot match the ultimate structural load capacity of high-tensile steel countersunk bolts. |

| Installation | Compatible with standard Phillips head bolts tools. Requires less specialized handling than exotic metals. | Limited UV Resistance: Unfilled PEEK can be susceptible to UV degradation during prolonged outdoor exposure. |

Applications

PEEK screws are specified in demanding, mission-critical environments where their cost is justified by their unbeatable performance profile.

Aerospace and Defense: Used in internal components, radar systems, and aircraft interiors where lightweight, high-strength, non-flammable fasteners are mandatory.

Medical and Analytical Equipment: Fastening components in surgical instruments and sterilization equipment (autoclave cycles) due to chemical resistance and high heat tolerance.

Oil and Gas: Downhole tools and sensors requiring stability under high pressure, high temperature, and exposure to corrosive hydrocarbons.

High-Temperature Electronics: Securing components in furnaces, soldering machines, and other devices operating above $200^\circ \text{C}$. PEEK often replaces countersunk stainless bolts in these scenarios to reduce weight and thermal conductivity.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.