PFA Flat washer

PFA Flat washer is a precision-engineered washer made from Perfluoroalkoxy (PFA),Extreme Chemical and Thermal Resistance

M Size: M4-M10

peek plastic material:Polyvinylidenefluoride(PFA)

product type: Washers

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PFA Flat washer Overview

PFA Flat Washer is an elite non-metallic component chosen for applications demanding the highest level of chemical inertness, purity, and thermal resistance. PFA (Perfluoroalkoxy Alkane) is a fluoropolymer, sharing the exceptional non-stick and chemical properties of PTFE (Teflon), but possessing superior melt-processability and clarity。

Overview and Design

| Feature | Detail | Purpose |

| Material (PFA) | Perfluoroalkoxy Alkane. A high-purity fluoropolymer with extreme chemical and thermal stability. | Ensures the fastener assembly is completely immune to corrosion and contamination. |

| Design (Flat Washer) | A simple, non-threaded annular disk. | Distributes the load evenly over a wider surface area to prevent damage, protect the substrate, and maintain the tightness of the PFA bolt and nut assembly. |

| Purity | Ultra-High Purity. Non-leaching and non-contaminating. | Essential for use in sterile, cleanroom, and ultra-pure water (UPW) systems. |

Product Parameters

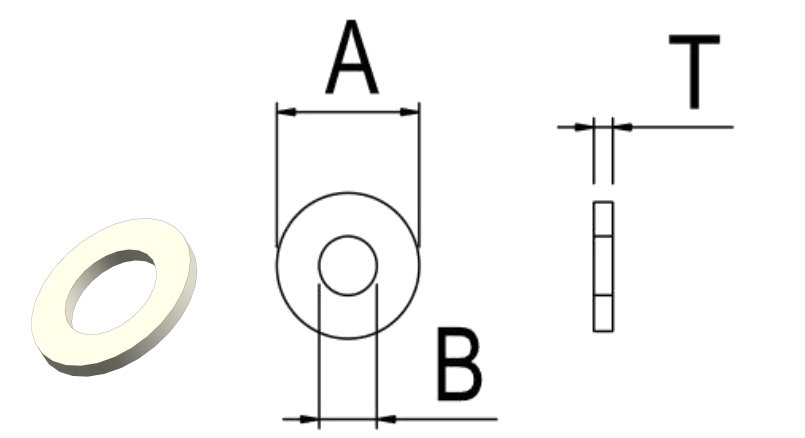

PFA Flat Washers typically follow metric standards, such as ISO 7089/7090 (Plain Washers), with dimensions specified by the inner diameter (ID), outer diameter (OD), and thickness (T). The ID corresponds to the nominal diameter of the bolt it will fit.

| Nominal Size (Bolt d) | Inner Diameter (ID) | Outer Diameter (OD) | Thickness (T) |

| M3 | 3.2 mm | 7.0 mm | 0.5 mm |

| M4 | 4.3 mm | 9.0 mm | 0.8 mm |

| M5 | 5.3 mm | 10.0 mm | 1.0 mm |

| M6 | 6.4 mm | 12.0 mm | 1.6 mm |

| M8 | 8.4 mm | 16.0 mm | 1.6 mm |

| M10 | 10.5 mm | 20.0 mm | 2.0 mm |

Key Features

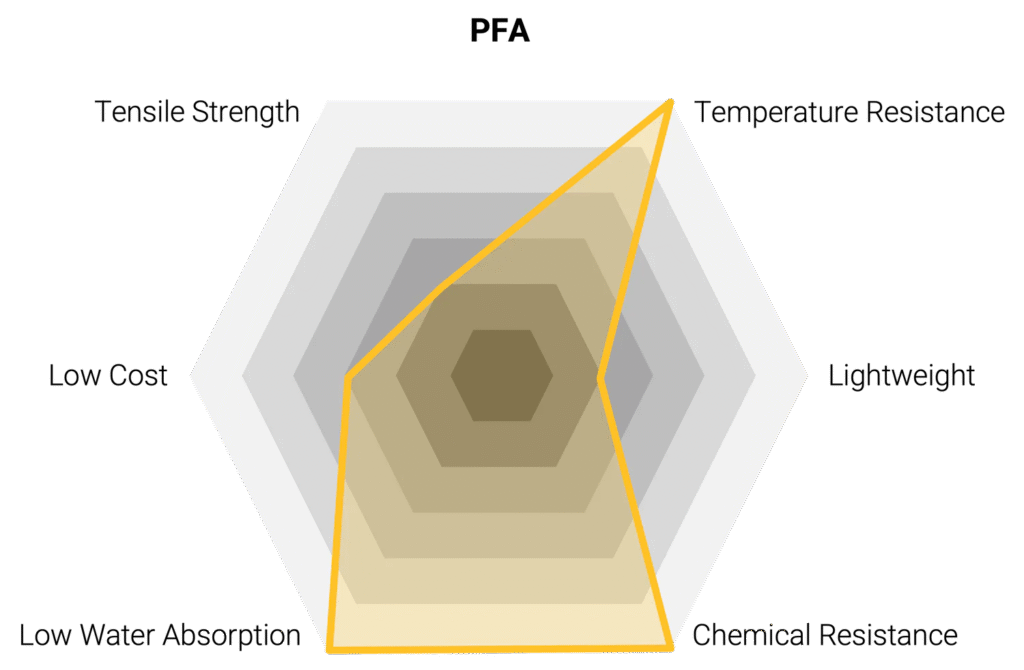

PFA’s properties, derived from its fluorine-based structure, place it in the same class as PEEK for extreme environments but with superior chemical resistance:

Universal Chemical Inertness: PFA is virtually non-reactive to all chemicals, solvents, and acids up to very high temperatures, making it the most chemically resistant non-metal washer available.

Extreme Thermal Resistance: It offers a high maximum service temperature, often up to 260°C(500°C), far surpassing flat rubber washer or flat washer nylon alternatives.

Anti-Stick/Low Friction: Inherits the excellent non-stick properties of fluoropolymers, reducing friction and preventing material build-up.

High Purity and Low Leaching: Ideal for ultra-pure water systems and semiconductor manufacturing, as it does not contaminate the surrounding medium.

Excellent Dielectric Properties: It is a superb electrical insulator, maintaining its properties across a wide temperature range.

Toughness and Wear: PFA is generally tougher and less prone to cold flow (deformation under pressure) than PTFE, giving it better load-bearing characteristics than other fluoropolymers.

Key Perfluoro alkoxyalkane (PFA) Properties

Applications

PFA Flat Washers are non-negotiable in the most critical, high-purity, and chemically aggressive applications.

Semiconductor Manufacturing: Essential in chemical delivery systems and wet benches due to its ultra-high purity and resistance to highly corrosive etchants.

Chemical Processing: Used in sensitive valves, pumps, and piping in environments where failure of even a stainless flat washer would be catastrophic.

Pharmaceutical and Food Processing: Utilized in components requiring extreme chemical cleaning and resistance to high-temperature steam sterilization.

Aerospace and Defense: Used as an insulating and protective spacer in high-heat zones where chemical exposure is possible.

Corrosion Control: Employed in assemblies where the washer must act as an impervious barrier, eliminating the galvanic corrosion risk that necessitates comparing lock washer and flat washer materials.

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Performance | Unmatched Chemical Inertness: Resistant to virtually all known chemicals. Extreme Temperature Tolerance: Maintains integrity up to 260°C. | Cost: PFA is a premium fluoropolymer, making the washers extremely expensive—often cost-prohibitive for non-critical applications. |

| Functionality | High Purity: Does not leach contaminants into ultra-pure liquids 。 Superior Toughness: Better resistance to creep and wear than PTFE. | Mechanical Strength: Despite its toughness, the tensile strength is much lower than metal flat washer options. |

| Comparison | Solves the primary corrosion and purity issues that necessitate comparing lock washer vs flat washer options. Vastly superior to washer flat nylon in both heat and chemical aggression. | Torque Limitations: Requires careful installation torque to prevent material deformation, unlike the high torque tolerance of a metal flat lock washer. |

| Sourcing | Available in precise dimensions conforming to flat washer specs and sizing standards. | Availability: Specialized product requiring sourcing from dedicated fluoropolymer suppliers, unlike commodity flat wash products. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.