PFA Hexagon nut

PFA Hexagon nut is known as the “King of Plastics”. It is corrosion-resistant and electrically insulating. It is not affected by temperature and can be used for a long time at -80~260℃.

M Size: M5-M10

peek plastic material:Polyvinylidenefluoride(PFA)

product type: Nuts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PFA Hexagon Nuts Overview

PFA (Perfluoroalkoxy Alkane) Hexagon Nut is an ultra-high-performance fastening component, offering near-universal chemical resistance and extreme thermal stability unrivaled by standard polymer or metal nuts. It is the ideal partner for PFA bolts, threaded rods, or metal threads in applications where corrosion, contamination, and high temperatures are the primary design challenges.

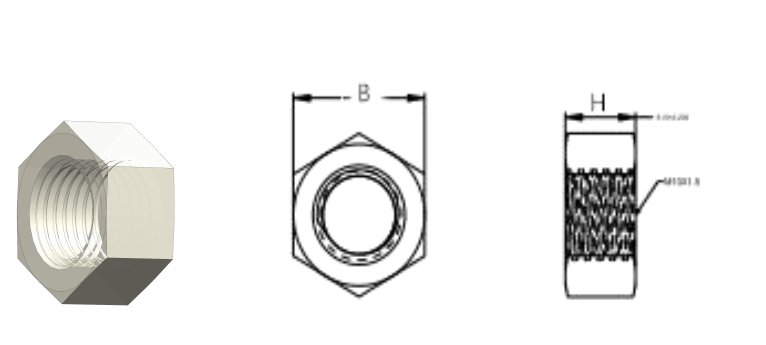

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PFA) | Perfluoroalkoxy Alkane. A high-purity fluoropolymer with extreme chemical and thermal stability. | Ensures the assembled joint is completely immune to corrosion and chemical attack. |

| Design (Hexagon Nut) | Standard six-sided external shape. | Allows for easy tightening and high torque transfer using common wrenches (spanners), enabling secure assemblies. |

| Purity | Ultra-High Purity. Non-leaching and non-contaminating. | Essential for use in cleanroom, pharmaceutical, and ultra-pure water (UPW) systems. |

| Function | Used with PFA or metal bolts/threaded rods. | Provides the required clamping force to secure two or more components together. |

Product Parameters

PFA Hexagon Nuts typically follow metric standards, such as ISO 4032 (Hexagon regular nuts), ensuring compatibility with standard metric tools and bolts.

| Nominal Size (Bolt d) | Thread Pitch (P) | Across Flats (s) | Nut Height (m) |

| M3 | 0.5 mm | 5.5 mm | 2.4 mm |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm |

| M5 | 0.8 mm | 8.0 mm | 4.7 mm |

| M6 | 1.0 mm | 10.0 mm | 5.2 mm |

| M8 | 1.25 mm | 13.0 mm | 6.4 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 10.0 mm |

Key Features

PFA Hexagon Nuts are chosen specifically for their superior environmental performance:

Extreme Chemical Resistance: Unaffected by virtually all industrial chemicals, solvents, and concentrated acids up to its maximum service temperature.

Thermal Stability: Maintains integrity and chemical resistance from cryogenic lows up to approximately 260°C(500°C).

Corrosion & Galvanic Immunity: Completely eliminates the risk of rust, corrosion, or galvanic interaction when paired with metal components.

Sealing Capability: PFA’s inherent slight softness aids in creating a secure, leak-resistant seal when tightened against a flat surface or PFA washer.

Non-Conductive & Non-Magnetic: Provides essential electrical isolation for sensitive equipment.

Advantages and Disadvantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Unmatched Chemical and Thermal Resistance. Excellent seal maintenance in corrosive media. Zero contamination. | Low Mechanical Strength: Cannot withstand the high tensile/clamping forces of metal nuts. |

| Material | Non-corrosive, Non-magnetic, Excellent Insulator. | Cold Flow (Creep): PFA is prone to deforming permanently under sustained, high compressive pressure, which may lead to joint loosening over time. |

| Cost | Provides the highest level of purity and resistance available in a fastening component. | Very High Cost due to specialized material and complex manufacturing processes. |

Applications

PFA Hexagon Nuts are used in the most critical, demanding environments across high-technology sectors:

Semiconductor Manufacturing: Used in cleanroom assemblies, wet etching tools, and chemical delivery systems to prevent metallic ion contamination.

Chemical Processing: Fastening flanges, valves, and pipe joints exposed to aggressive, hot processing fluids.

Ultra-High Purity (UPW) Systems: Essential for all structural fastening where absolute zero contamination is required.

High-Temperature Equipment: Securing components within ovens, sterilizers, and processing equipment operating at extreme temperatures.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.