PFA Slotted pan head screw

PFA Slotted pan head screw is known as the “King of Plastics”. It is corrosion-resistant and electrically insulating. It is not affected by temperature and can be used for a long time at -80~260℃.

M Size: M4-M10

peek plastic material:Polyvinylidenefluoride(PFA)

product type: Pan head bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

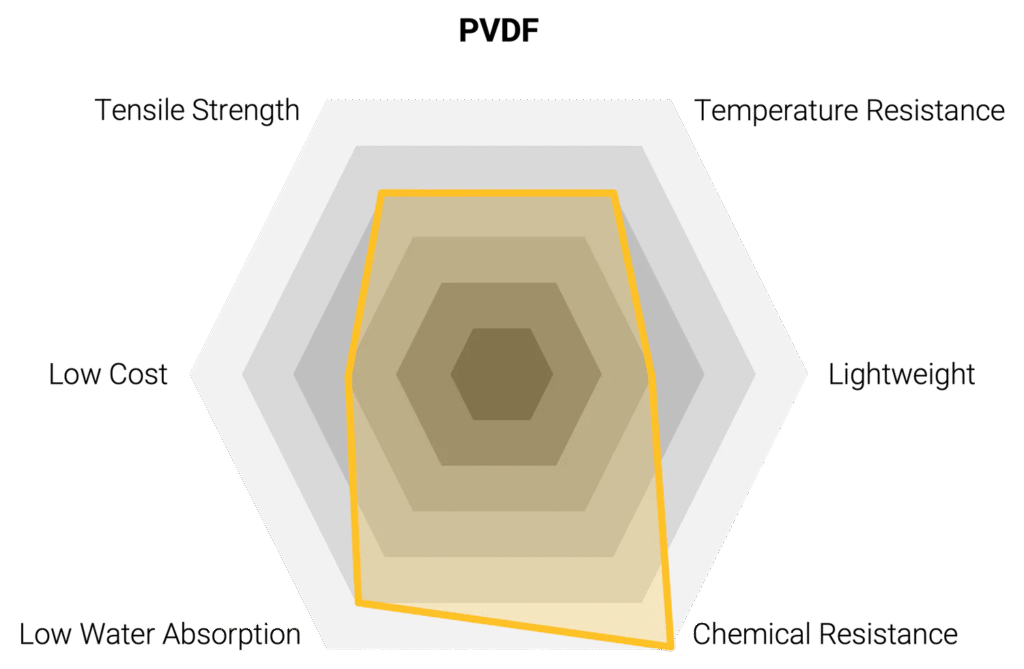

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PFA Slotted pan head screw Overview

PFA (Perfluoroalkoxy Alkane) Slotted Pan Head Screw is an exceptionally high-purity, high-performance plastic screw. It combines the superior chemical and thermal resistance of PFA with the large clamping surface of a Pan Head design, making it ideal for assemblies requiring a strong seal, zero contamination, and tolerance for extreme environments.

Overview and Design

| Feature | Detail | Purpose |

| Material (PFA) | Perfluoroalkoxy Alkane. Provides near-universal chemical inertness and the highest thermal stability among melt-processable fluoropolymers. | Ensures the fastener is immune to corrosion and stable across extreme temperature changes. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and resistance to pull-through. |

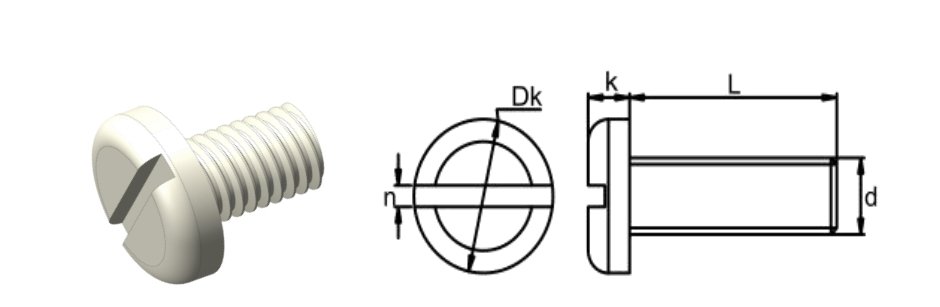

Product Parameters

PFA Slotted Pan Head Screws typically adhere to the dimensional standards of ISO 1580 (Slotted Pan Head Screws) or equivalents. Since PFA has lower mechanical strength than metal, installation torque must be strictly managed.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (N) |

| M3 | 0.5 mm | 6.0 mm | 2.0 mm | 0.8 mm |

| M4 | 0.7 mm | 8.0 mm | 2.6 mm | 1.0 mm |

| M5 | 0.8 mm | 9.5 mm | 3.3 mm | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 3.9 mm | 1.6 mm |

| M8 | 1.25 mm | 14.0 mm | 5.2 mm | 2.0 mm |

Key Features

PFA screws are selected for their performance limits, offering benefits unmatched by metals or standard plastics:

Near-Universal Chemical Inertness: Unaffected by virtually all industrial chemicals, solvents, and acids up to its maximum service temperature.

Extreme Thermal Stability: Maintains integrity and chemical resistance from cryogenic lows up to approximately 260°C(500°C).

Ultra-High Purity: Non-leaching and non-contaminating, essential for high-purity fluid handling and sterile environments.

Large Clamping Area: The Pan Head design allows for secure fastening without overly stressing the PFA material during compression.

Non-Conductive and Non-Magnetic: Ideal for sensitive electronic and diagnostic equipment.

Key Perfluoro alkoxyalkane (PFA) Properties

Advantages VS Disadvantage

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Highest Chemical and Thermal Resistance of common polymer screws. Excellent sealing capability due to large head diameter. | Low Mechanical Strength: The soft nature of PFA means it cannot sustain high tensile loads. |

| Design | Immune to corrosion; Pan Head offers wide bearing surface. | Slotted drive is prone to tool slip (cam-out) and limits installation torque. |

| Material | Very High Cost due to specialized material and manufacturing processes. | Prone to creep or cold flow under sustained high compression, potentially leading to loosening over time. |

Applications

- Semiconductor equipment

- Chemical pumps and valves

- Medical equipment

- Food industry

- Aerospace

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.