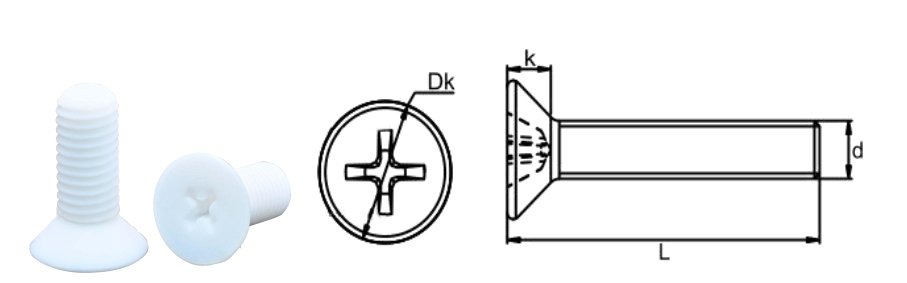

PP Cross counter sunk head screw

PP Cross counter sunk head screw has a specific gravity of 0.9, which is the lightest among plastics; it has excellent mechanical properties, good chemical stability; excellent electrical properties, and is resistant to high-frequency electrical insulation.

M Size: M2-M12

peek plastic material: PP Polypropylene

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PP Cross counter sunk head screw Overview

PP (Polypropylene) Cross Countersunk Head Screws are lightweight, economical, and corrosion-resistant fasteners used in low-to-medium load applications. They provide a flush-mount design similar to metal countersunk bolts, countersunk head bolts, and phillips head bolts, but with the benefits of polypropylene’s flexibility, chemical resistance, and moisture-proof performance.

Product Parameters

PP countersunk bolts are manufactured to standard specifications, focusing on sizes commonly used in consumer goods, water systems, and electronics assembly, including common options like countersunk m4 bolts and larger 3/8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) | Key Application Area |

| M3 | #4 | 6.0 mm / 0.24 in | Consumer electronics, Small housings |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in | Appliance assembly, Electrical isolation |

| M6 | 1/4″ | 12.0 mm / 0.47 in | Water filtration components |

| M10 | 3/8″ (3/8 countersunk bolt) | 18.0 mm / 0.71 in | Large non-structural assemblies |

Key Features

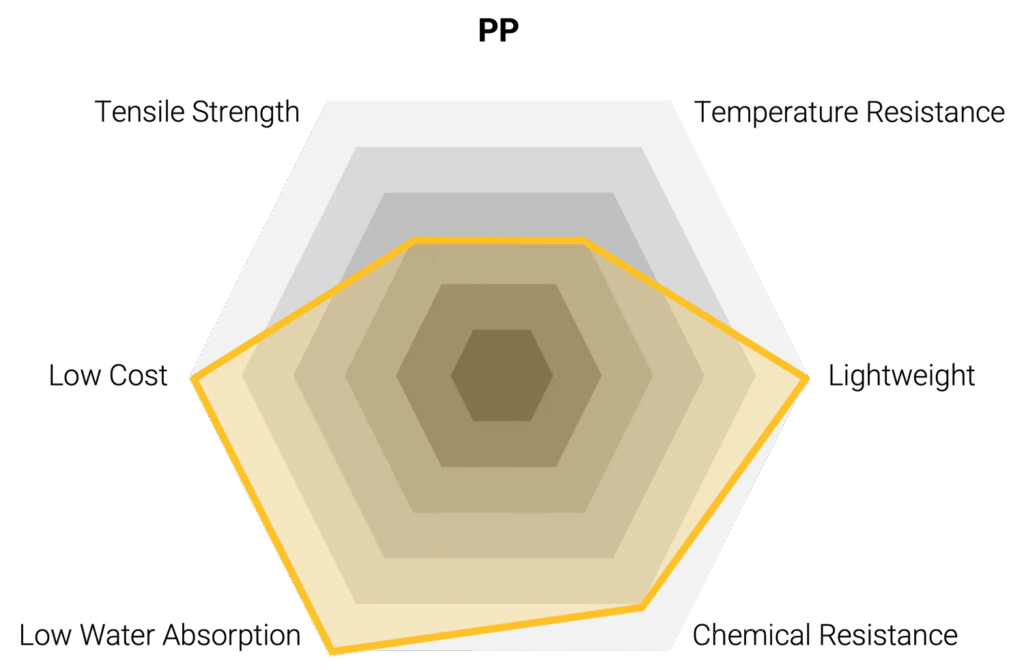

PP screws offer specific advantages, particularly in environments involving water and common chemicals, while maintaining a very low price point.

Excellent Chemical Resistance: Highly resistant to many acids, alkalis, salts, and organic solvents. It is stable in environments involving water and steam.

Low Density: Polypropylene is one of the lightest commercial plastics, offering a significant weight advantage over any metal countersunk bolts or even other plastics.

Good Fatigue Resistance: PP can withstand a high number of bending cycles without failure, making it suitable for snap-fit or flexible applications.

Low Moisture Absorption: It maintains dimensional stability well in wet or humid environments, unlike Nylon.

Cost-Effective: PP is one of the most economical plastics available for manufacturing plastic screws.

Key Polypropylene (PP) Properties

Advantages and Disadvantages (Pros and Cons)

The choice of PP balances its superb chemical resistance and low cost against its limited performance in high-stress or high-temperature environments.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Environmental Performance | Excellent Chemical Resistance (acids, bases). Very Low Moisture Absorption. Non-Toxic and Recyclable. | Poor UV Resistance: Prone to degradation and cracking under sunlight unless stabilized. |

| Mechanical Performance | Very Lightweight. High Fatigue Resistance (good for flexible components). | Low Thermal Resistance: Softens significantly above 100°C. Lower Tensile Strength than most other plastic screws. |

| Cost | Most Cost-Effective option among all chemical-resistant plastic fasteners. | Structural Limitation: Cannot handle the high loads or torque of metal countersunk bolts. |

Applications

PP screws are specified in non-critical structural applications where chemical resistance and low cost are prioritized over high mechanical strength or extreme heat resistance.

Water Filtration/Plumbing: Used in housings, pumps, and filters due to its excellent resistance to water and many treatment chemicals.

Laboratory Equipment: Fastening non-structural components exposed to common laboratory reagents.

Consumer Appliances: Used extensively in dishwashers, washing machines, and refrigerator components.

Toys and Furniture: General assembly where low cost, light weight, and a non-corrosive screws solution are needed.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.