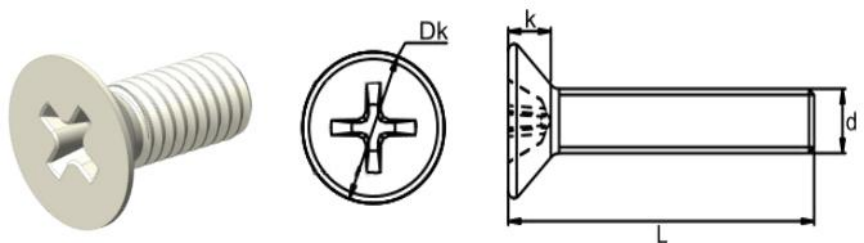

PPS Cross counter sunk head screw

PPS Cross counter sunk head screw are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M2-M10

peek plastic material: Polyetherether ketone(PPS)

product type:Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Cross counter sunk head screw Overview

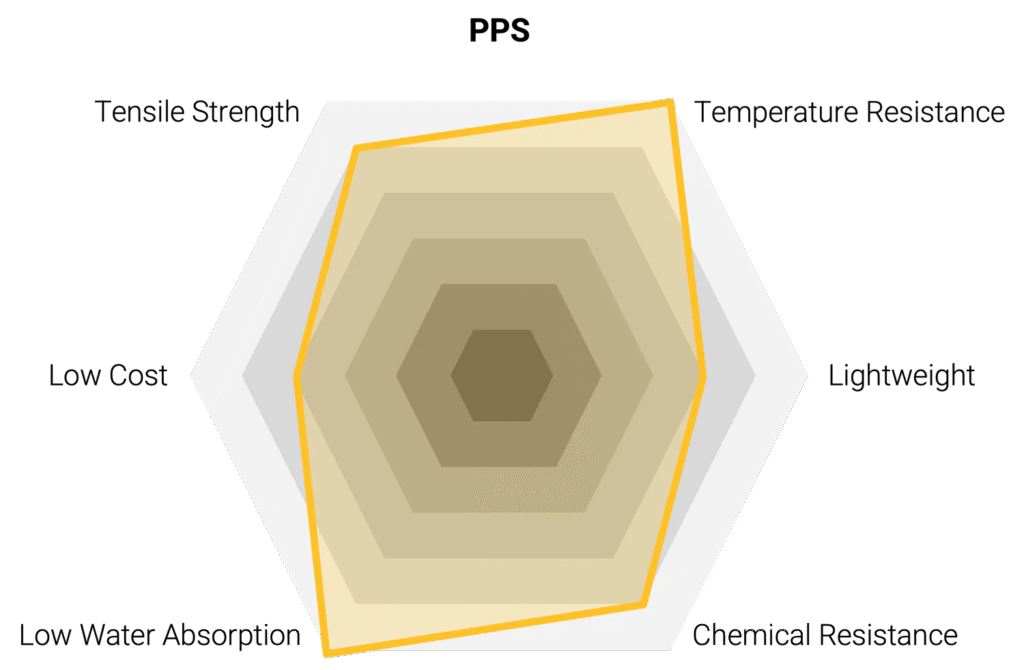

PPS (Polyphenylene Sulfide) is a high-performance engineering thermoplastic, renowned for its exceptional thermal stability, chemical inertness, and inherent flame resistance. The PPS Cross Countersunk Head Screw is a critical plastic fastener designed for applications that require a balance of mechanical strength, high operating temperature tolerance, and corrosion resistance.

Product Parameters

PPS fasteners are produced to meet standard metric and imperial specifications, allowing for direct replacement of traditional metal hardware. Common sizes include precision countersunk m4 bolts and larger structural options like the 3/8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) | Key Application Area |

| M3 | #4 | 6.0 mm / 0.24 in | Circuit Boards, Sensors |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in | Electrical Enclosures, Housings |

| M6 | 1/4″ | 12.0 mm / 0.47 in | Industrial Controls, Small Pumps |

| M10 | 3/8″ (3/8 countersunk bolt) | 18.0 mm / 0.71 in | Chemical Processing Equipment |

Key Features

PPS screws are chosen when stability under heat and chemical attack is paramount, offering a superior alternative to many standard plastic screws and even some metal countersunk bolts.

Excellent Thermal Stability: PPS maintains its mechanical properties up to 200°C(392°C), making it ideal for hot environments.

Superior Chemical Resistance: Highly resistant to a broad spectrum of acids, alkalis, and solvents, often outperforming many grades of countersunk stainless bolts in chemically aggressive media.

Inherent Flame Retardancy: Naturally rated UL 94 V-0 without the need for additives, making it safe for electrical and electronic assemblies.

High Rigidity: Offers excellent stiffness and creep resistance, providing dependable long-term fastening performance.

Good Dielectric Properties: Excellent electrical insulator, crucial for electrical separation and safety.

Key Polypropylene (PP) Properties

Advantages and Disadvantages (Pros and Cons)

The decision to use PPS involves weighing its superior thermal and chemical stability against the absolute structural strength offered by metal bolt assemblies.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Environmental Performance | Excellent Thermal Stability (up to 200°C). Superior Chemical Inertness and Inherent Flame Retardancy. | Lower Structural Load: Cannot handle the extreme tension or shear loads of steel or titanium countersunk bolts. |

| Mechanical Performance | High Stiffness and Rigidity. Good Dimensional Stability at high temperatures. | Brittleness: Can be brittle, especially in unfilled grades, requiring careful installation torque control. |

| Cost | Cost-effective alternative to ultra-high-performance plastics (like PEEK). | Higher Cost than common engineering plastics (e.g., Nylon, PVC). |

Applications

PPS screws are specified primarily in industrial, automotive, and electronic applications that involve continuous high temperatures and corrosive exposure.

Automotive Under-the-Hood: Used in sensors, pumps, valves, and other components exposed to high heat, fuels, and coolants.

Electrical and Electronics: Securing components, terminals, and coil forms due to its thermal stability and inherent flame resistance.

Industrial Machinery: Fastening parts in dryers, furnaces, and processing equipment where resistance to aggressive industrial fluids and heat is required.

Chemical Processing: Used in components within filtration units, metering devices, and piping systems that handle hot, corrosive media.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.