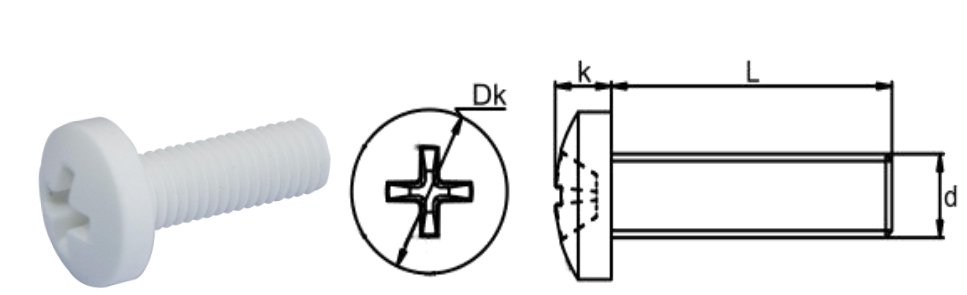

PPS Cross pan head screw

PPS Cross pan head screw are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M2-M12

peek plastic material: Polyetherether ketone(PPS)

product type:Pan head bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Cross pan head screw Overview

PPS (Polyphenylene Sulfide) Cross Pan Head Screw is a high-performance plastic screw designed for applications requiring exceptional chemical and thermal resistance combined with high mechanical stiffness. The Pan Head design provides a wide bearing surface, and the Cross (Phillips) drive allows for efficient installation using standard tools.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PPS) | Polyphenylene Sulfide. A semicrystalline polymer known for its high mechanical strength, high dimensional stability, and service temperature up to $220^\circ \text{C}$. | Ensures the fastener maintains structural integrity and chemical immunity in extreme operating conditions. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and pull-through resistance. |

Product Parameters

PPS Cross Pan Head Screws adhere to established metric standards for cross-recess pan head screws, such as ISO 7045 (or equivalents like DIN 7985).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Cross Recess Size (PH) |

| M3 | 0.5 mm | 6.0 mm | 2.4 mm | PH1 |

| M4 | 0.7 mm | 8.0 mm | 3.1 mm | PH2 |

| M5 | 0.8 mm | 9.5 mm | 3.7 mm | PH2 |

| M6 | 1.0 mm | 10.5 mm | 4.2 mm | PH3 |

| M8 | 1.25 mm | 14.0 mm | 5.3 mm | PH3 |

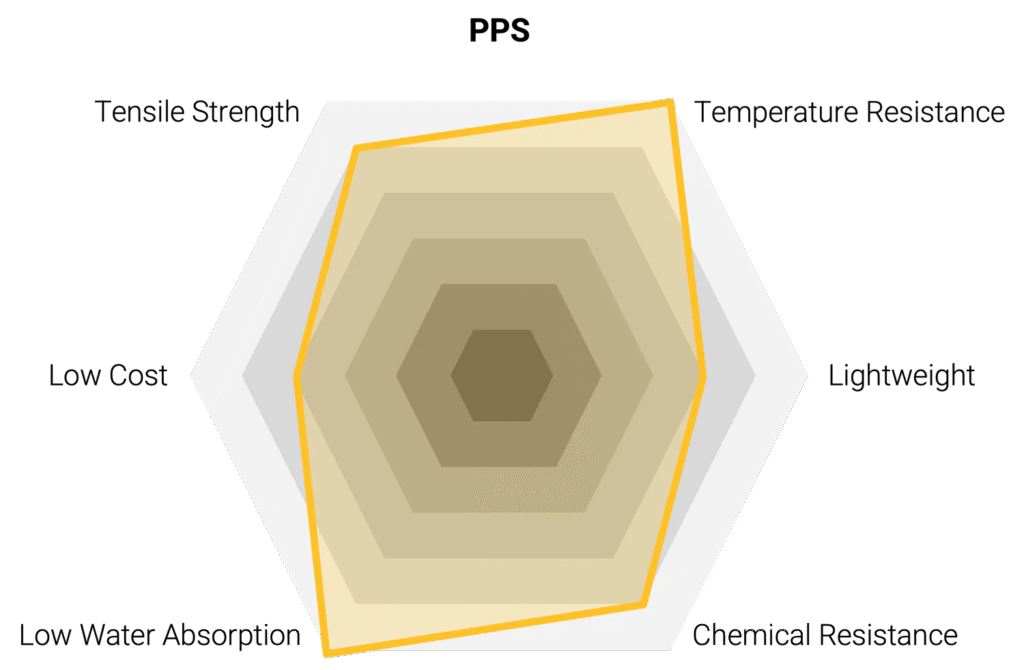

Key Features

Excellent heat resistance: Heat deflection temperature reaches over 260°C, and the continuous operating temperature is between 200-220°C.

Excellent chemical resistance: It is virtually insoluble in all organic solvents below 200°C. It is highly resistant to acids, alkalis, salts, and fuels.

Inherent flame retardancy: UL94 flame retardancy rating reaches V-0, achieved without the addition of any flame retardants.

Excellent dimensional stability and low moisture absorption: Moisture absorption is extremely low (approximately 0.02%), resulting in minimal dimensional change in high temperature and humidity environments.

Excellent mechanical strength and rigidity: High rigidity and hardness, but relatively brittle and with average impact toughness.

Key Polypropylene (PP) Properties

Applications

- Electrical Equipment: Insulation and fastening for high-voltage switchgear and heating elements, ensuring high-temperature resistance and flame retardancy.

- Automotive: Engine peripheral components (sensor covers, ignition coils), water pump impellers, and fuel system components.

- Chemical Equipment: Assembly of pumps, valves, and pipe flanges, ensuring resistance to acid, alkali, and solvent corrosion.

- Household Appliances: Components requiring high-temperature resistance, such as electric irons, hair dryers, and microwave ovens.

- Special Applications: Lightweight fastening for MRI medical equipment (non-magnetic) and semiconductor tools (low-pollution).

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Superior chemical and thermal resistance over standard engineering plastics (Nylon, PC). High rigidity and creep resistance. | Lower Impact Strength: More brittle than Nylon or PC; care must be taken during installation to prevent fracture. |

| Design | Pan Head provides superior pull-through resistance. Cost-effective for high-performance requirements. | Cross Drive Limitation: Provides limited torque transmission; easily stripped if over-torqued. |

| Material | Lightweight, non-corrosive, excellent dimensional stability. | Higher cost than standard engineering plastics. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.