PPS Hexagon head bolt

PPS Hexagon head bolts are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M3-M8

peek plastic material: Polyetherether ketone(PPS)

product type: Hexagon head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Hexagon head bolt Overview

PPS (Polyphenylene Sulfide) Hexagon Head Bolt is a high-performance, structural plastic fastener known for its exceptional chemical resistance, high mechanical stiffness, and excellent thermal stability (up to 220°C). The Hexagon Head design allows for high, controlled tightening, making it suitable for secure, load-bearing assemblies in extremely harsh environments where conventional plastics or metals would fail.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PPS) | Polyphenylene Sulfide. A semicrystalline polymer known for its high mechanical strength, high dimensional stability, and superior thermal performance. | Ensures the fastener maintains structural integrity and chemical immunity in extreme operating conditions. |

| Head Style (Hex Head) | Standard six-sided external head. | Designed for maximum wrench grip, allowing for the highest installation torque achievable with PPS, enabling secure clamping. |

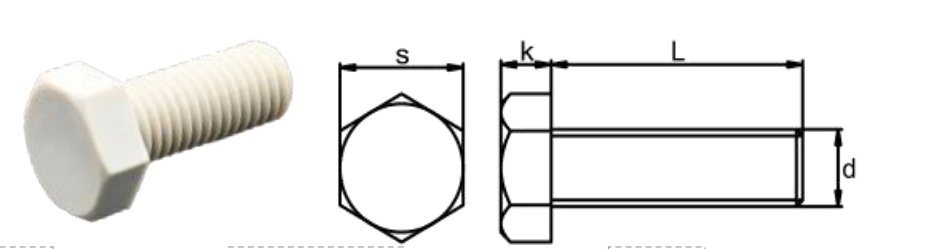

Product Parameters

PPS Hexagon Head Bolts typically follow established metric standards for hexagon head bolts, such as ISO 4014 (partially threaded) or ISO 4017 (fully threaded).

| Nominal Diameter (d) | Thread Pitch (P) | Across Flats (s) | Head Height (k) |

| M5 | 0.8 mm | 8.0 mm | 3.5 mm |

| M6 | 1.0 mm | 10.0 mm | 4.0 mm |

| M8 | 1.25 mm | 13.0 mm | 5.3 mm |

| M10 | 1.5 mm | 16.0 mm | 6.4 mm |

| M12 | 1.75 mm | 18.0 mm | 7.5 mm |

| M16 | 2.0 mm | 24.0 mm | 10.0 mm |

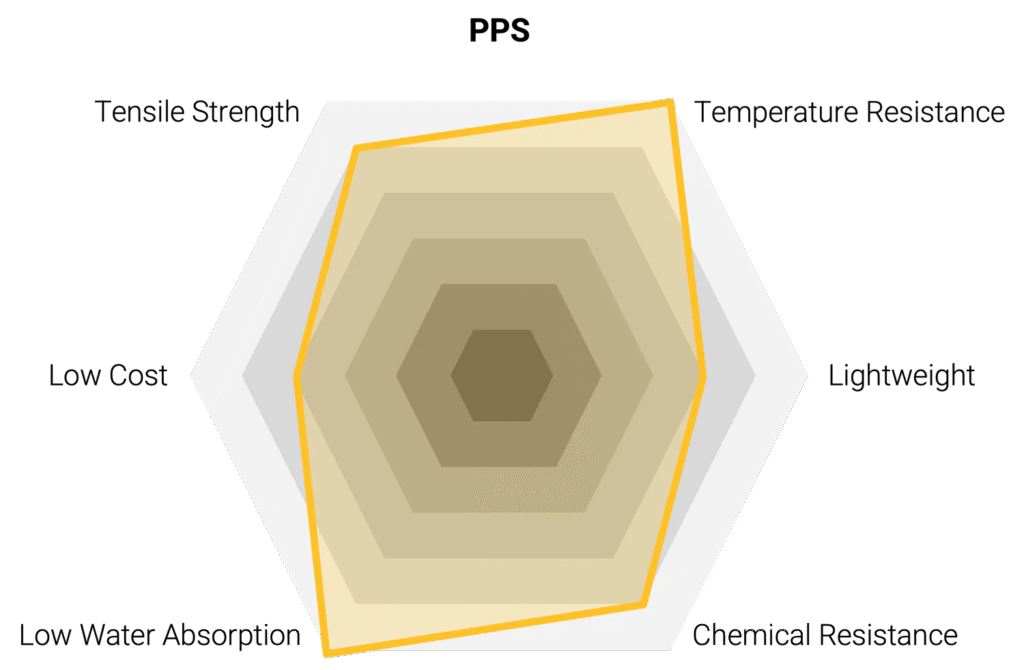

Key Features

PPS fasteners are selected for their combination of high stiffness, strength, and superior environmental performance:

High Thermal Stability: Maintains strong mechanical properties at continuous operating temperatures up to 220°C (428°C).

Exceptional Chemical Resistance: Highly resistant to a vast range of aggressive solvents, fuels, and acids, offering near-universal chemical immunity.

High Mechanical Stiffness: Very rigid, offering excellent resistance to creep (deformation under sustained load) and maintaining thread engagement at high temperatures.

Dimensional Stability: Low thermal expansion and minimal moisture absorption compared to materials like Nylon.

Non-Conductive & Non-Magnetic: Essential for electrical and sensitive instrumentation assemblies.

Key Polypropylene (PP) Properties

Applications

PPS Hexagon Head Bolts are critical in industrial applications exposed to severe environments:

Automotive: Securing engine components, transmission parts, and fluid systems where high heat, engine oil, and fuels are present.

Chemical Processing: Structural fastening of pumps, valves, and piping in systems handling aggressive chemicals at elevated temperatures.

Electrical Equipment: Mounting heavy electrical components, busbars, and insulators in high-heat environments.

Ovens and Sterilizers: Used in internal fixtures requiring long-term resistance to heat, steam, and hot water.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Superior chemical and thermal resistance over standard engineering plastics. High rigidity and excellent creep resistance. | Lower Impact Strength: More brittle than Nylon or PC; care must be taken during high-impact loading. |

| Design | Hex Head allows for the maximum installation torque achievable with PPS, enabling strong clamping. | Higher Cost: More expensive than standard polymers, though often more cost-effective than PEEK for similar performance. |

| Material | Lightweight, non-corrosive, excellent dimensional stability. | Limited temperature range compared to PEEK ($260^\circ \text{C}$), but still exceptionally high. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.