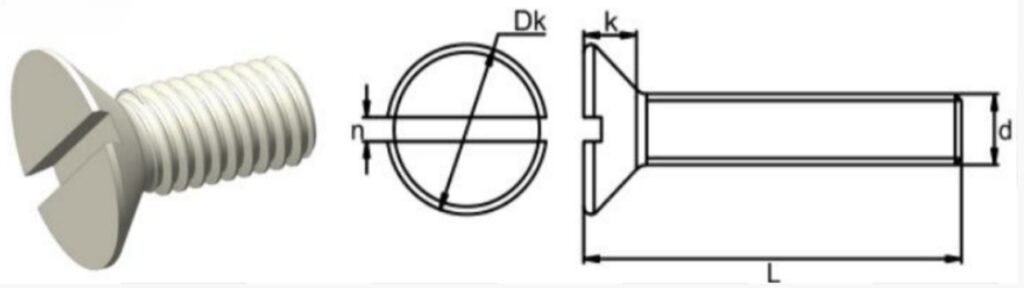

PPS Slotted counter sunk head screw

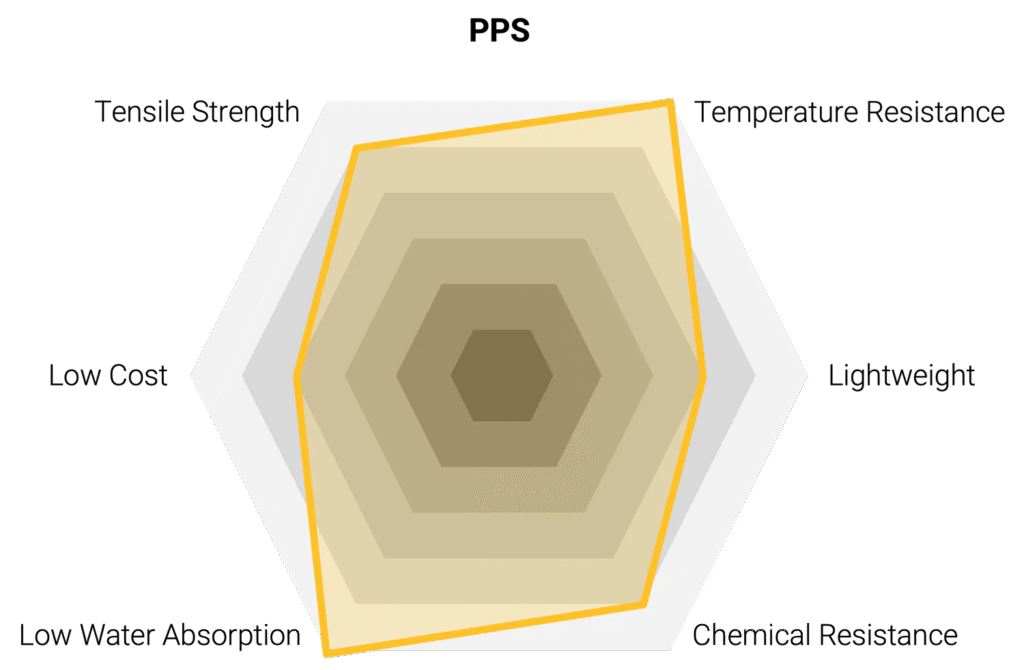

PPS Slotted counter sunk head screw are made of a hard, highly rigid material with excellent heat resistance, chemical resistance, and dimensional stability.

M Size: M2-M10

peek plastic material: Polyetherether ketone(PPS)

product type: Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PPS Slotted counter sunk head screw Overview

PPS (Polyphenylene Sulfide) Slotted Countersunk Head Screw is a high-performance plastic screw designed for applications requiring exceptional chemical and thermal resistance combined with a flush, smooth surface finish. The Countersunk Head (Flat Head) recesses entirely into the material, and the Slotted Drive allows for conventional tool installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PPS) | Polyphenylene Sulfide. A semicrystalline polymer with high mechanical strength, dimensional stability, and service temperature up to 220°C. | Ensures the fastener maintains structural integrity and chemical immunity under extreme conditions. |

| Head Style (Countersunk/Flat Head) | Features a flat top surface and a tapered underside (conical). | Designed to recess into a prepared hole, allowing the head to sit flush with the surface for a smooth, clean finish. |

| Drive Style (Slotted) | A simple single slot on the top surface. | Allows for installation using a flat-blade screwdriver; suitable for low-to-moderate torque applications. |

Product Parameters

PPS Slotted Countersunk Head Screws typically follow metric standards for slotted countersunk head screws, such as ISO 2009 (Slotted Countersunk Flat Head Screws).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Angle | Slot Width (N) |

| M3 | 0.5 mm | 5.6 mm | 90°C | 0.8 mm |

| M4 | 0.7 mm | 7.5 mm | 90°C | 1.0 mm |

| M5 | 0.8 mm | 9.2 mm | 90°C | 1.2 mm |

| M6 | 1.0 mm | 11.0 mm | 90°C | 1.6 mm |

| M8 | 1.25 mm | 14.5 mm | 90°C | 2.0 mm |

Key Features

The Countersunk design, coupled with PPS material, provides high functionality in harsh settings:

Superior Environmental Resistance: Maintains integrity at continuous temperatures up to 220°C and resists a vast range of aggressive chemicals, solvents, and fuels.

Flush Finish: Creates a smooth, snag-free surface, essential in cleanrooms, fluid handling, and abrasive environments.

High Mechanical Stiffness: Very rigid and highly resistant to creep (deformation under sustained load) at elevated temperatures.

Hydrolysis Resistance: Excellent performance in hot water and steam environments.

Non-Contaminating: Ideal for semiconductor and food processing where zero contamination is required.

Key Polypropylene (PP) Properties

Applications

PPS Slotted Countersunk Head Screws are critical in industrial applications exposed to severe environments where a smooth surface is necessary:

Semiconductor Manufacturing: Fastening panels and components in cleanrooms where non-contamination and a smooth, non-particulate-trapping surface are mandatory.

Chemical Processing: Securing access panels, sight glasses, and instrumentation covers in systems handling hot or corrosive chemicals.

Food and Beverage: Used in processing equipment where fasteners must resist high-temperature cleaning (CIP) and aggressive sanitizers while remaining non-contaminating.

High-Temperature Fixtures: Fastening components inside drying ovens, sterilizers, and industrial heating equipment.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Aesthetics/Function | Creates a smooth, snag-free, flush surface. Superior thermal and chemical resistance. | Requires Preparation: Installation requires a precise countersunk hole, adding a manufacturing step. |

| Performance | High rigidity and creep resistance. Cost-effective for high-performance requirements. | Lower Impact Strength: More brittle than Nylon or PC; risk of fracture under high-impact loading. |

| Design | Suitable for highly corrosive/high-heat applications. | Slotted Drive Limitation: Provides low torque transmission and is easily stripped if over-torqued. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.