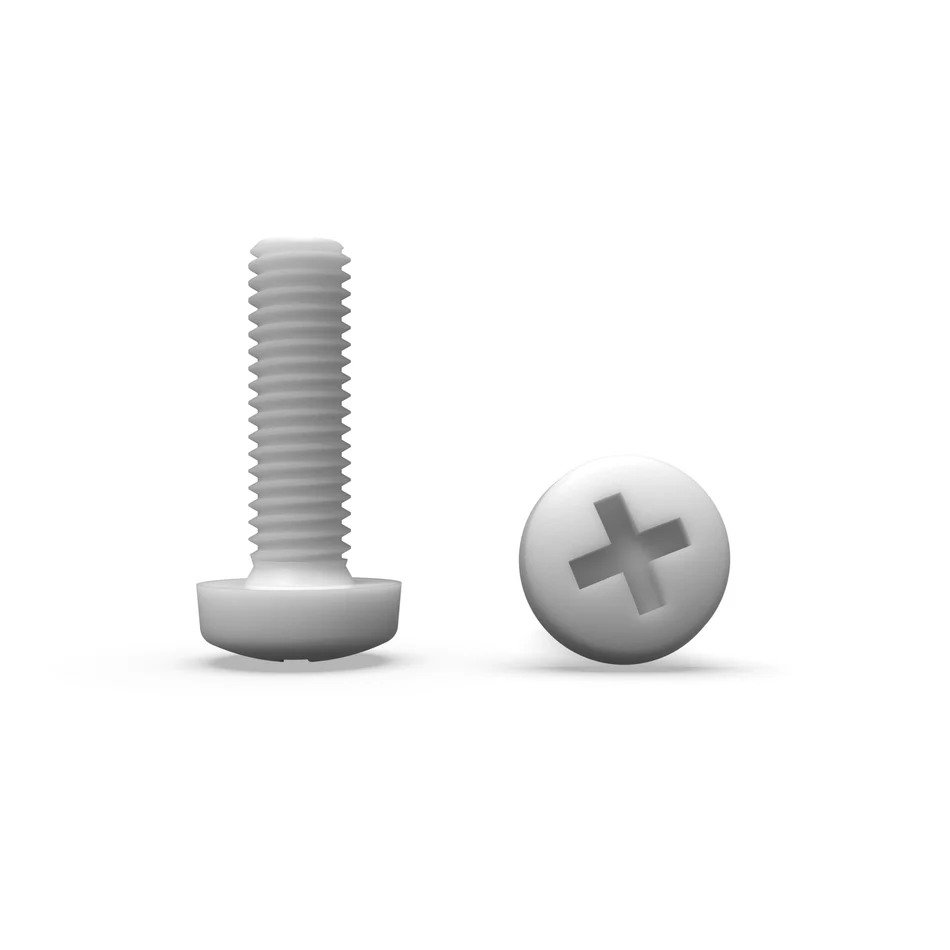

PTFE Cross pan head screw

PTFE Cross pan head screw has excellent chemical stability, corrosion resistance, heat resistance and cold resistance, flame retardant grade UL94 V-0, and can be used for a long time at -190~260℃.

M Size: M3-M12

peek plastic material: Polytetra fluoroe thylene(PTFE )

product Type: Pan head bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PTFE Cross pan head screw Overview

PTFE (Polytetrafluoroethylene, or Teflon) Cross Pan Head Screw is a premium, high-performance fluoropolymer fastener renowned for its exceptional chemical inertness, wide temperature stability, and high purity. The Pan Head provides a wide bearing surface, and the Cross (Phillips) drive allows for fast, efficient installation, though torque must be strictly limited due to the material’s softness.

PTFE Cross Pan Head Screw: Overview, Specifications, and Applications

The PTFE (Polytetrafluoroethylene, or Teflon) Cross Pan Head Screw is a premium, high-performance fluoropolymer fastener renowned for its exceptional chemical inertness, wide temperature stability, and high purity. The Pan Head provides a wide bearing surface, and the Cross (Phillips) drive allows for fast, efficient installation, though torque must be strictly limited due to the material’s softness.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PTFE) | Polytetrafluoroethylene. A high-performance fluoropolymer with the lowest coefficient of friction and highest chemical inertness of all plastics. | Provides a fastener that is virtually impervious to all industrial chemicals and functions across an extremely wide temperature range. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for clamping and pull-through resistance. |

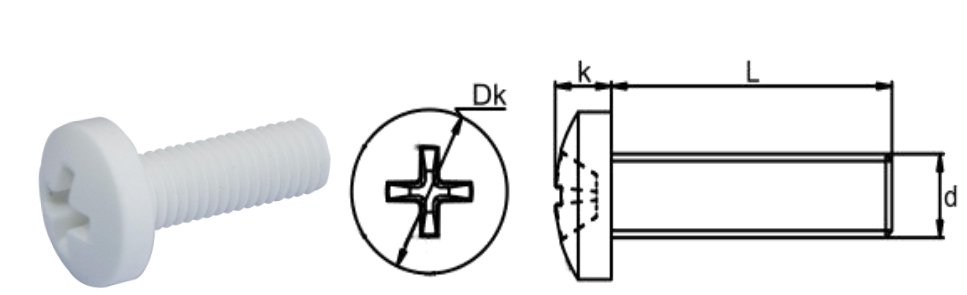

Product Parameters

PTFE Cross Pan Head Screws typically follow metric standards for cross-recess pan head screws, such as ISO 7045 (or equivalents like DIN 7985).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Cross Recess Size (PH) |

| M3 | 0.5 mm | 6.0 mm | 2.4 mm | PH1 |

| M4 | 0.7 mm | 8.0 mm | 3.1 mm | PH2 |

| M5 | 0.8 mm | 9.5 mm | 3.7 mm | PH2 |

| M6 | 1.0 mm | 10.5 mm | 4.2 mm | PH3 |

| M8 | 1.25 mm | 14.0 mm | 5.3 mm | PH3 |

Key Features

PTFE fasteners are defined by their extreme chemical and thermal performance, offset by their mechanical limitations:

Universal Chemical Inertness: Unaffected by virtually all industrial chemicals, solvents, and corrosive agents, including hydrofluoric acid and strong caustics.

Extreme Temperature Range: Operates reliably from approximately 200°Cto $+260°C。

Lowest Friction: Extremely low coefficient of friction makes it ideal for non-stick surfaces and non-lubricated applications.

High Purity: Does not leach contaminants, vital for pharmaceutical and ultra-pure processes.

Non-Conductive: Excellent dielectric strength, offering superior electrical insulation.

Advantages and Disadvantages and Usage Scenarios

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Highest chemical and temperature resistance of all plastics. Excellent non-stick and non-contaminating properties. | Low Mechanical Strength: Very soft with high cold flow (creep) under load. | Chemical Reactors/Piping: Securing covers and access ports exposed to highly aggressive acids and solvents. |

| Design | Pan Head provides superior pull-through resistance for the material’s limited strength. Cross drive allows for fast installation. | Torque Restriction: Must be installed with very low, controlled torque to prevent thread stripping and joint relaxation over time. | Cryogenic/High-Heat Equipment: Fastening internal components in systems operating at temperature extremes (e.g., 150°Cor 250°C). |

| Environmental | Non-corrosive, UV resistant (though primarily an indoor material), non-magnetic. | High Cost: Significantly more expensive than PVDF or Nylon. | Pharmaceutical/Food Processing: Non-contaminating assemblies where steam or aggressive sanitizers are use |

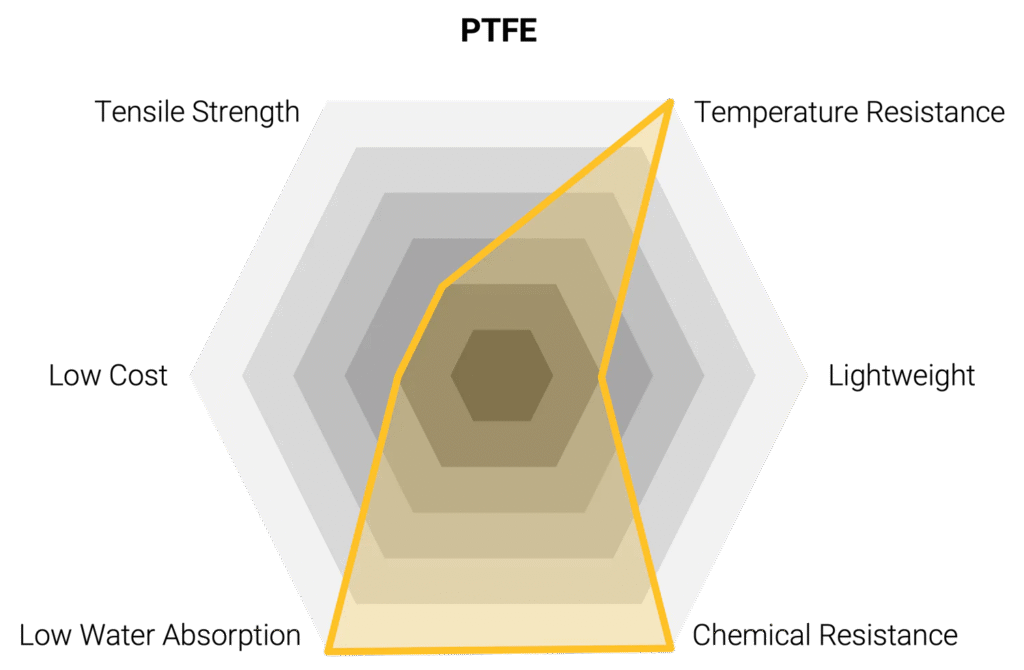

Key Polytetrafluoroethylene (PTFE) Properties

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.