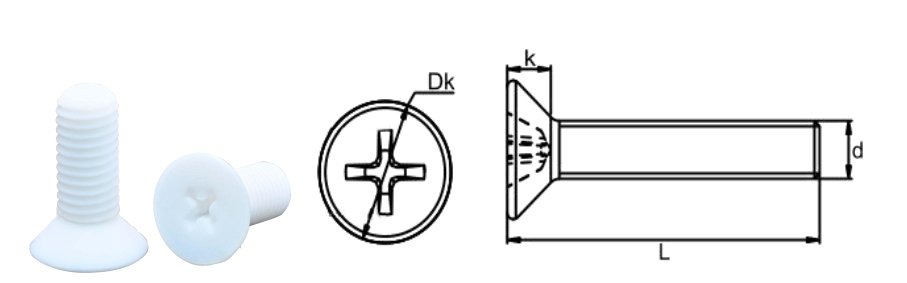

PTFE Crosscounter sunk head screw

PTFE Crosscounter sunk head screw has excellent chemical stability, corrosion resistance, heat resistance and cold resistance, flame retardant grade UL94 V-0, and can be used for a long time at -190~260℃.

M Size: M3-M10

peek plastic material: Polytetra fluoroe thylene(PTFE )

product Type: Countersunk bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PTFE Crosscounter sunk head screw Overview

PTFE (Polytetrafluoroethylene) Cross Countersunk Head Screws are premium fluoropolymer plastic fasteners known for their exceptional chemical resistance, extremely low friction, non-stick behavior, and outstanding temperature stability. With a countersunk head that sits flush to the surface, these screws offer the functional advantages of metal countersunk bolts, phillips head bolts, and countersunk head bolts, while delivering unique PTFE benefits such as non-wetting properties, electrical insulation, and superior corrosion resistance.

Product Parameters

PTFE countersunk bolts are manufactured to precise standards, focusing on common sizes used in high-tech and chemical processing facilities, including standard metric sizes like countersunk m4 bolts and imperial sizes like the 3/8 countersunk bolt.

| Metric Size (M) | Imperial Size (in) | Head Diameter (D) | Key Application Area |

| M3 | #4 | 6.0 mm / 0.24 in | Sensor mounting, Thin enclosures |

| M4 (Countersunk M4 bolts) | #6 | 8.0 mm / 0.31 in | Electrical boards, Small fluid components |

| M6 | 1/4″ | 12.0 mm / 0.47 in | Piping joints, Pump assemblies |

| M10 | 3/8″ (3/8 countersunk bolt) | 18.0 mm / 0.71 in | Large filter housings, Chemical tanks |

Key Features

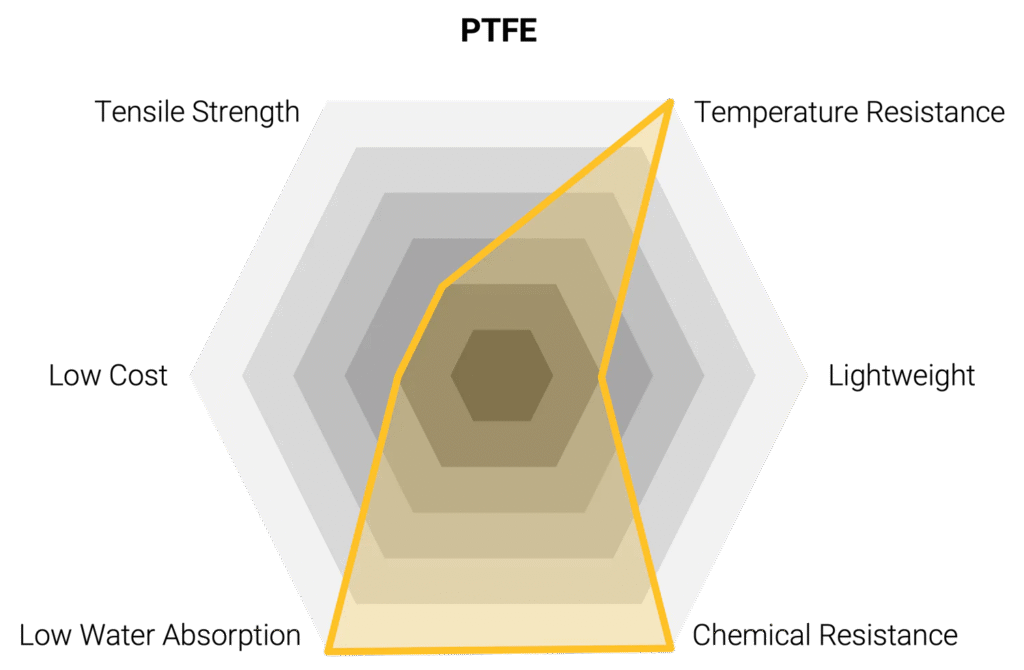

PTFE fasteners are specified when absolute chemical reliability and minimal friction are required, making them unique even among specialized plastic screws.

Near-Universal Chemical Inertness: PTFE is chemically resistant to almost all industrial chemicals, acids, bases, and solvents up to its maximum service temperature. It is entirely immune to corrosion, unlike countersunk stainless bolts.

Wide Thermal Range: Maintains its mechanical and chemical stability from cryogenic temperatures up to approximately 260°C(500°C).

Ultra-Low Friction (Non-Stick): It has one of the lowest coefficients of friction of any solid material, which is key in reducing wear and preventing material buildup.

High Purity: Non-leaching and non-contaminating, making it indispensable for ultra-pure water (UPW) and pharmaceutical systems.

Excellent Electrical Insulator: Superior dielectric strength, making it effective for electrical isolation across a wide range of frequencies.

Key Polytetrafluoroethylene (PTFE) Properties

Advantages and Disadvantages (Pros and Cons)

Choosing PTFE means prioritizing chemical and thermal stability above all else, often accepting mechanical trade-offs.

| Category | Advantage (Pro) | Disadvantage (Con) |

| Environmental Performance | Near-Universal Chemical Resistance. Extremely Wide Operating Temperature Range. Ultra-High Purity & Non-Stick. | Creep/Cold Flow: Prone to deforming or loosening over time under constant compressive load, requiring careful design and occasional re-tightening. |

| Mechanical Performance | Superior Low-Friction properties. Excellent resistance to environmental stress cracking. | Low Mechanical Strength: The weakest structural strength of all high-performance polymers (e.g., weaker than PEEK or PPS). |

| Cost | Highest reliability and purity in chemical service. | Very High Cost: One of the most expensive plastic screws on the market, limiting its use to necessary applications. |

Applications

PTFE screws are critical components in environments where material contact must be absolutely minimized, and corrosion is rampant.

Semiconductor Wet Processing: Securing components in etch baths, chemical delivery systems, and UPW lines due to its extreme purity and resistance to aggressive chemicals.

Chemical Processing: Fastening components inside reactors, vessels, and piping systems handling concentrated acids (e.g., Hydrofluoric Acid) and strong oxidizers.

Food and Pharmaceutical Production: Used in non-contact components where non-stick properties and inertness are required to prevent contamination.

Cryogenic Applications: Fastening components exposed to extremely low temperatures, where its resistance to brittle failure is essential.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.