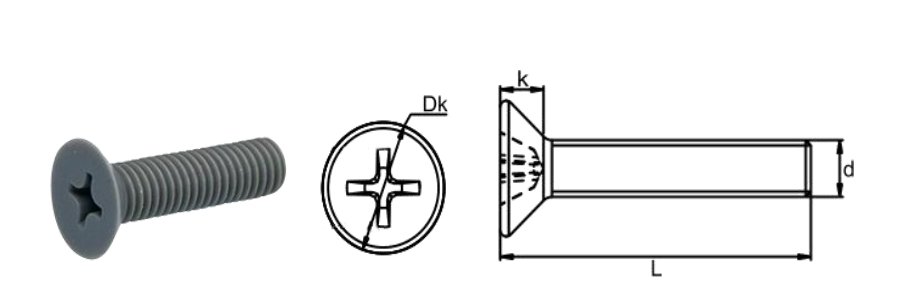

PVC Cross counter sunk head screw

PVC Cross counter sunk head screw: Corrosion Resistance and Flush Finish

M Size: M2-M10

peek plastic material: Polyvinylchloride(PVC )

product type: Countersunk bolts

color: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVC Cross counter sunk head screw Overview

PVC Cross Countersunk Head Screw is an economical and highly effective non-metallic fastener made from Polyvinyl Chloride (PVC). It is distinguished by its excellent chemical and moisture resistance and its countersunk head, which allows for a clean, flush surface installation. It is a common choice where a standard bolt or countersunk stainless bolts would corrode, but high mechanical strength is not the primary requirement.

Product Parameters

Metric (M) PVC Countersunk Cross Head Screws:

| Thread Size D | Pitch P (mm) | Major Diameter (mm) | Recommended Tapping Drill Diameter (mm) |

| M3 | 0.5 | 3.00 | 2.50 |

| M4 | 0.7 | 4.00 | 3.30 |

| M5 | 0.8 | 5.00 | 4.20 |

| M6 | 1.0 | 6.00 | 5.00 |

| M8 | 1.25 | 8.00 | 6.80 |

| M10 | 1.5 | 10.00 | 8.50 |

| M12 | 1.75 | 12.00 | 10.20 |

Key Features

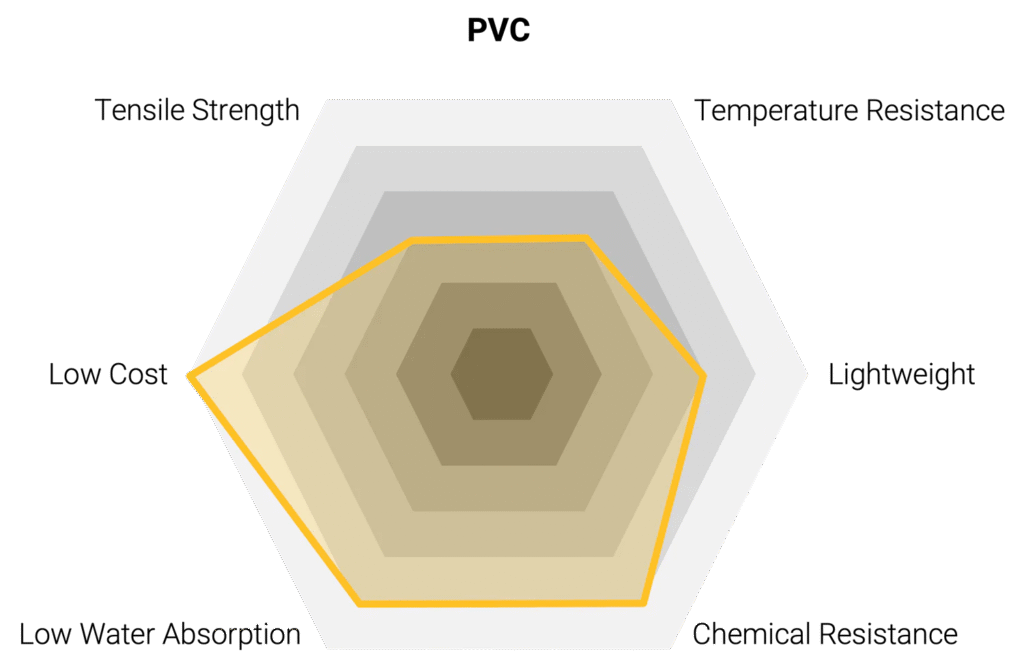

The essential features of the PVC Cross Countersunk Head Screw are derived from the PVC polymer:

Excellent Chemical Resistance: PVC is highly resistant to water, moisture, acids, alkalis, and salts, making it superior to standard metal fasteners (like unplated steel countersunk bolt).

Corrosion Immunity: As a non-metal, it offers absolute resistance to rust and galvanic corrosion, a critical advantage over countersunk stainless bolts in certain aggressive environments.

Electrical Insulation: It is non-conductive, providing reliable dielectric strength and preventing short circuits.

Cost-Effectiveness: PVC is a commodity plastic, making its fasteners highly economical for high-volume manufacturing.

Flush Installation: The countersunk head ensures a clean, smooth finish, crucial for safety or aerodynamic surfaces.

Key Polyvinyl Chloride (PVC) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Protection | Superior Corrosion Immunity and excellent moisture resistance. Prevents galvanic corrosion. | Low Mechanical Strength: Significantly lower tensile strength and shear strength than metal countersunk bolt options, limiting load capacity. |

| Design | Flush Surface Finish is ideal for clean, smooth aesthetics and safety. Cost-Effective for mass production. | Temperature Limit: Low maximum service temperature (approx. $60^\circ \text{C}$ / $140^\circ \text{F}$), making it unsuitable for hot environments. |

| Functionality | Reliable Electrical Insulation. Available in standard imperial (3 8 countersunk bolt) and metric (countersunk m4 bolts) sizes. | Torque Limitation: Must be installed with very low torque to prevent stripping the polymer threads or cracking the countersunk head. |

| Installation | Compatible with common phillips head bolt drivers. | Countersinking Required: Installation requires a precise countersunk hole for the head to sit flush; otherwise, the head will protrude. |

Applications

PVC Cross Countersunk Head Screws are widely used in assemblies exposed to moisture or corrosive chemicals where a smooth, non-protruding surface is required.

Plumbing and Waterworks: Used to secure covers, inspection panels, and fixtures where exposure to water and cleaning agents is guaranteed.

Chemical and Laboratory Equipment: Employed in non-critical assemblies, ventilation ducts, and lab furniture where fasteners must resist corrosive fumes and spills.

Outdoor and Marine Fixtures: Used in outdoor furniture, decking, and marine equipment where rust-free fastening and a smooth finish are necessary.

Aesthetic Assemblies: Utilized in display cases, covers, and consumer electronics where a smooth, clean appearance is desired.

Fastener Isolation: Used to secure panels where the screw must not conduct electricity or induce galvanic corrosion in a countersunk bolts and nuts assembly.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.