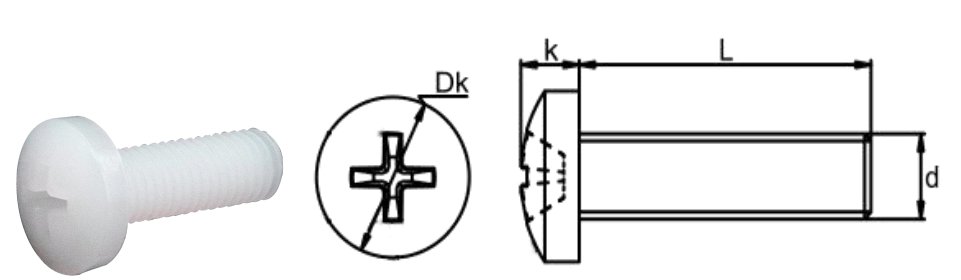

PVDF Cross pan head screw

PVDF Cross pan head screw is a polymer engineering plastic with excellent chemical and weather resistance, and excellent UV resistance and aging resistance.

M Size: M2-M12

peek plastic material: Polyvinylidene fluoride(PVDF)

product Type: Pan head bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVDF Cross pan head screw Overview

PVDF (Polyvinylidene Fluoride) Cross Pan Head Screw is a premium, high-performance fluoropolymer screw renowned for its exceptional purity, excellent chemical resistance (especially to halogens and strong oxidizers), and superior UV and weather resistance. The Pan Head provides a wide bearing surface, and the Cross (Phillips) drive allows for efficient, low-torque installation.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (PVDF) | Polyvinylidene Fluoride. A semicrystalline fluoropolymer with high stiffness, abrasion resistance, and excellent resistance to radiation and extreme environments. | Ensures outstanding chemical inertness, UV stability, and minimal contamination in highly critical systems. |

| Head Style (Pan Head) | Features a gently rounded top and vertical sides, maximizing the bearing surface for strong clamping and pull-through resistance. |

Product Parameters

PVDF Cross Pan Head Screws typically follow metric standards for cross-recess pan head screws, such as ISO 7045 (or equivalents like DIN 7985).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Cross Recess Size (PH) |

| M3 | 0.5 mm | 6.0 mm | 2.4 mm | PH1 |

| M4 | 0.7 mm | 8.0 mm | 3.1 mm | PH2 |

| M5 | 0.8 mm | 9.5 mm | 3.7 mm | PH2 |

| M6 | 1.0 mm | 10.5 mm | 4.2 mm | PH3 |

| M8 | 1.25 mm | 14.0 mm | 5.3 mm | PH3 |

Key Features

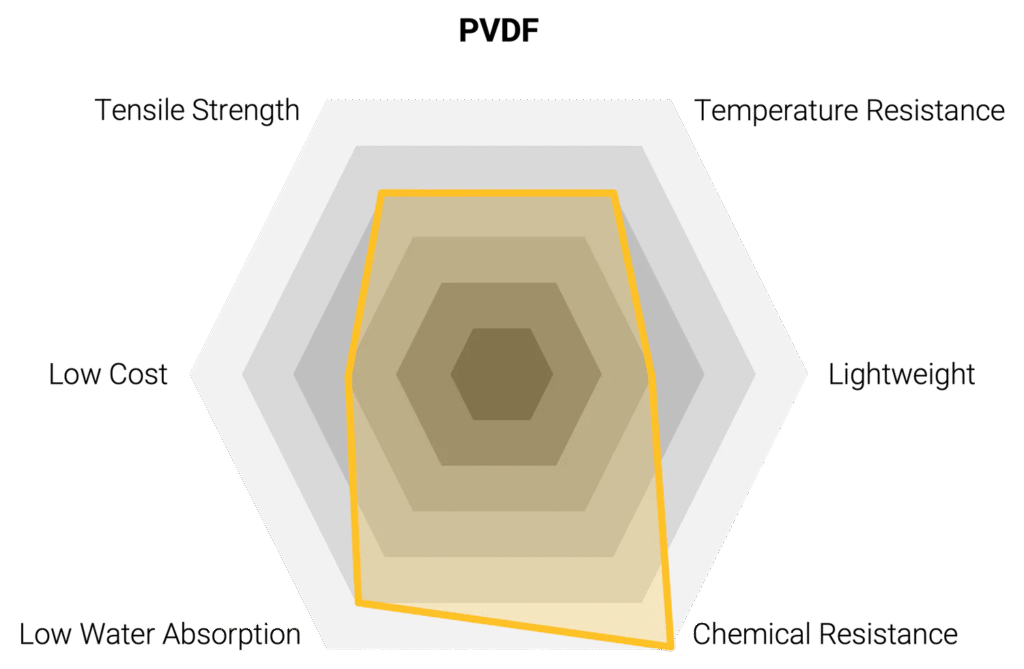

PVDF fasteners are selected for their combination of purity, stiffness, and environmental resilience:

Exceptional Chemical Resistance: Resists halogens (like chlorine), strong oxidizers (like nitric acid), and many solvents that attack other plastics.

Superior UV and Weather Resistance: Maintains color and mechanical properties indefinitely under direct sunlight and outdoor exposure, unlike Nylon or PVC.

High Purity: Does not leach contaminants, making it ideal for pure water systems and semiconductor manufacturing.

High Abrasion Resistance: Excellent wear properties, making it durable in sliding or dynamic applications.

Good Mechanical Strength: High stiffness and resistance to creep (deformation under sustained load).

Key Polyvinylidene fluoride (PVDF) Properties

Applications

PVDF Cross Pan Head Screws are critical in demanding applications where failure is costly or integrity is paramount:

Semiconductor Wet Benches: Fastening components, manifolds, and piping in systems handling aggressive cleaning acids and ultrapure water (UPW).

Chemical Processing: Securing covers and access points on storage tanks, valves, and filtration systems exposed to halogens and strong oxidizing agents.

Outdoor Chemical Storage: Used for external mounting where long-term UV resistance and chemical immunity are required.

Pharmaceutical and Food: Fastening components in contact with sanitizers and hot cleaning solutions where non-contamination is necessary.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Performance | Best-in-class UV, chemical, and abrasion resistance. Excellent purity and low smoke generation. | Cost: Significantly higher material cost than standard engineering plastics (Nylon, PP, PVC). |

| Design | Pan Head provides superior pull-through resistance. Service temperature up to 150°C. | Mechanical Strength: Lower tensile strength and thermal limit compared to PEEK (260°C). |

| Material | Lightweight, non-corrosive, non-magnetic, and non-conductive. | Cross Drive Limitation: Provides low torque transmission and is easily stripped if over-torqued. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.