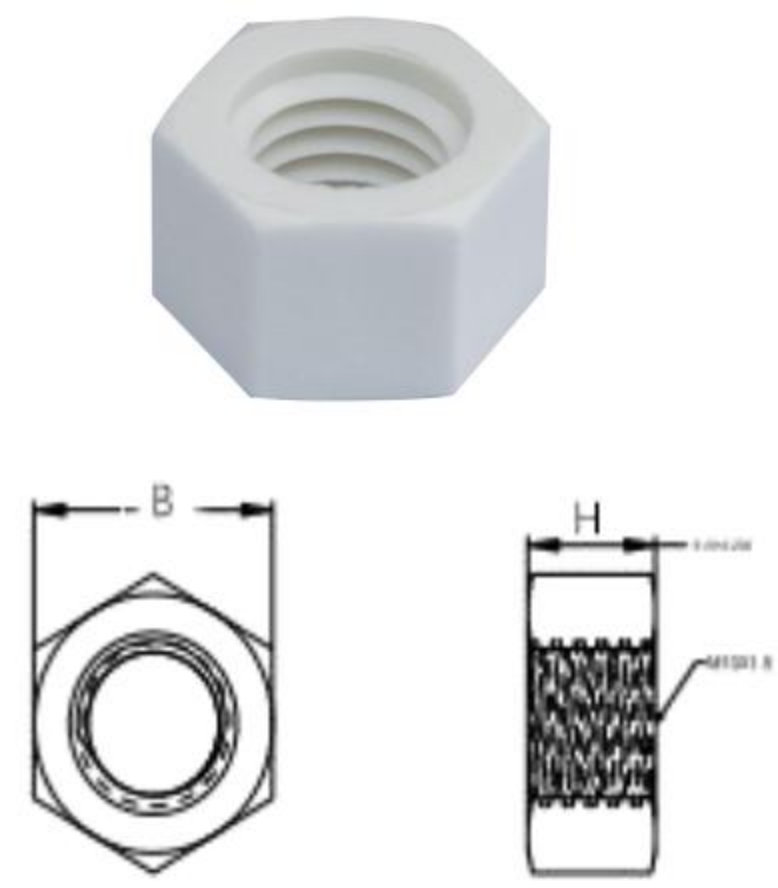

PVDF Hex nut

PVDF Hex nut is a polymer engineering plastic with excellent chemical and weather resistance, and excellent UV resistance and aging resistance.

M Size: M3-M30

peek plastic material: Polyvinylidene fluoride(PVDF)

product Type: Nuts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVDF Hex nut Overview

PVDF Hexagonal Nut is a high-performance, semi-crystalline thermoplastic fastener made from Polyvinylidene Fluoride. PVDF is highly valued for its exceptional abrasion resistance, good mechanical strength, and excellent chemical resistance, particularly to halogens and strong acids. It represents a balance between the universal chemical resistance of PTFE and the high mechanical strength of PEEK, offering a superior alternative to nylon hex nut and many stainless steel hex nuts in specific corrosive and abrasive environments.

Key Features

The unique properties of PVDF define the features of the PVDF Hexagon Nut:

Superior Abrasion Resistance: PVDF has excellent resistance to wear, tearing, and abrasion—often outperforming other fluoropolymers in dynamic or slurry applications.

Good Mechanical Strength: Offers significantly higher stiffness, tensile strength, and resistance to creep than PTFE, making it a more reliable load-bearing component in a hex nut bolt assembly.

Broad Chemical Resistance: Highly resistant to many aggressive chemicals, particularly halogens, organic solvents, and strong acids (including hot sulfuric acid).

High Purity and Low Leaching: Used in cleanroom applications and pharmaceutical processing where maintaining fluid purity is critical.

UV and Weather Resistance: Excellent resistance to UV light and weathering, making it highly suitable for long-term outdoor exposure.

High Thermal Stability: Maintains integrity at elevated service temperatures, typically up to 150°C(300°C).

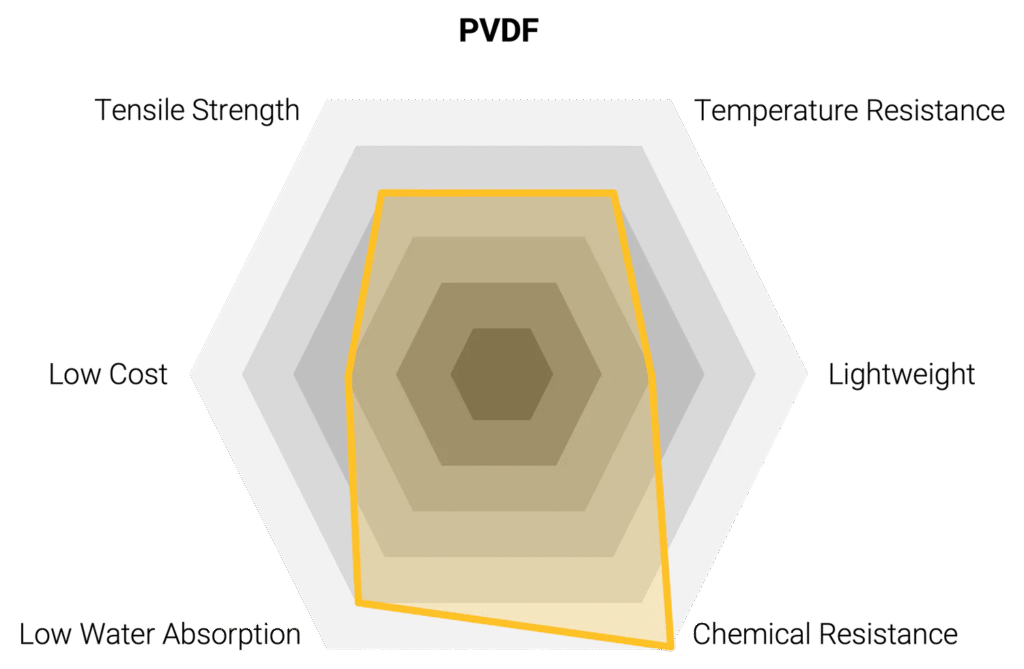

Key Polyvinylidene fluoride (PVDF) Properties

Advantages vs Disadvantages

| Category | ✅ Advantages (Pros) | ❌ Disadvantages (Cons) |

| Durability | Exceptional Abrasion/Wear Resistance. High Mechanical Strength (superior to PTFE). Excellent UV and Weather Resistance. | Cost: PVDF is a high-performance polymer, making the nuts significantly more expensive than nylon hex nut or commodity hex nuts. |

| Chemicals | Broad Chemical Resistance, particularly to halogens and strong acids. High Purity/Low Leaching. | Temperature Limit: While thermally stable, its maximum service temperature (approx. 150°C) is lower than PEEK or PTFE (260°C). |

| Functionality | Good stiffness and resistance to creep under load. Reliable electrical insulator. Solves the lock nut vs hex nut dilemma when chemical attack is primary. | Torque/Clamping: Requires careful installation torque to prevent crushing or thread damage, making it unsuitable for high-load applications with metal hex lock nuts. |

| Sourcing | Available in standard formats (metric hex nuts and imperial sizes). | Availability: Must be sourced from specialized polymer fastener suppliers, unlike commodity hex nuts or hex head nut products. |

Applications

PVDF Hexagon Nuts are essential in industries that handle harsh chemicals, particularly halogens, and require components that can withstand mechanical wear.

Chemical Processing and Piping: Used extensively in pipelines, pumps, and valves handling highly corrosive chemicals, including concentrated acids and chlorine, where even stainless steel hex nuts would corrode.

Semiconductor Manufacturing: Employed in ultra-pure water (UPW) systems and wet processing areas due to its low extractables and high purity.

Oil & Gas: Used in applications exposed to harsh downhole chemicals and abrasive slurries.

Outdoor and Architectural: Used in external fasteners where long-term UV resistance, weather resistance, and resistance to chemical cleaning agents are required.

Fastener Isolation: Used as a durable, non-conductive spacer to prevent galvanic corrosion between dissimilar metal fasteners in a bolt hex nut assembly.

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.