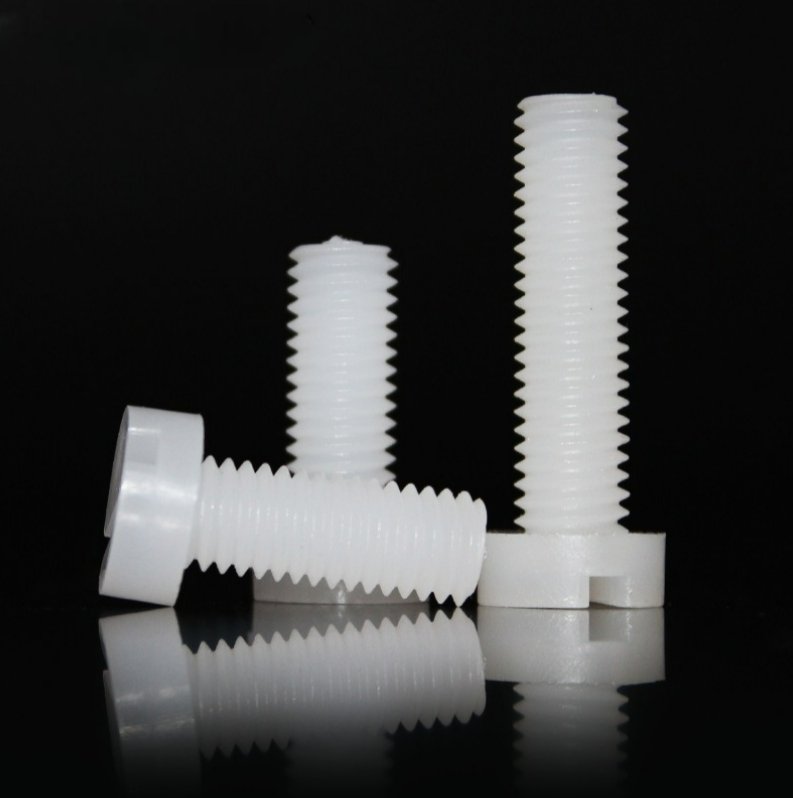

PVDF Slotted cheese head screw

PVDF Slotted cheese head screw is a polymer engineering plastic with excellent chemical and weather resistance, and excellent UV resistance and aging resistance.

M Size: M2-M10

peek plastic material: Polyvinylidene fluoride(PVDF)

product Type: Cylinder head bolts

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

PVDF Slotted cheese head screw Overview

PVDF (Polyvinylidene Fluoride) Slotted Cheese Head Screw is a premium, high-performance fluoropolymer fastener known for its exceptional purity, superior chemical resistance (especially to halogens and strong oxidizers), and excellent UV resistance. The Cheese Head (Cylindrical Head) design provides maximum material volume for high shear strength, while the Slotted Drive allows for conventional installation.

I. Overview and Design

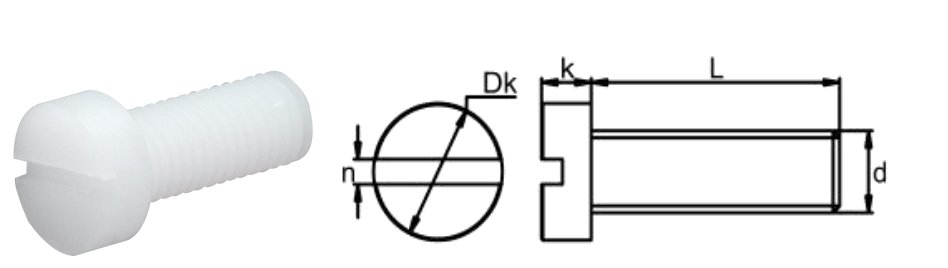

| Feature | Detail | Purpose |

| Material (PVDF) | Polyvinylidene Fluoride. A high-performance fluoropolymer with high stiffness, abrasion resistance, and excellent resistance to UV and aggressive chemicals. | Ensures chemical inertness, UV stability, and minimal contamination in highly critical systems. |

| Head Style (Cheese/Cylindrical Head) | A tall, cylindrical head with a large diameter. | Maximizes the head’s material volume and contact surface, providing excellent shear strength and resistance to lateral forces. |

| Drive Style (Slotted) | A simple single slot on the top surface. | Allows for easy installation and removal using a flat-blade screwdriver; suitable for low-to-moderate torque applications. |

Product Parameters

PVDF Slotted Cheese Head Screws typically follow metric standards for slotted cheese head screws, such as ISO 1207 (Slotted Cheese Head Screws) or similar industry specifications.

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Slot Width (N) |

| M3 | 0.5 mm | 5.5 mm | 2.4 mm | 0.8 mm |

| M4 | 0.7 mm | 7.0 mm | 3.2 mm | 1.0 mm |

| M5 | 0.8 mm | 8.5 mm | 4.0 mm | 1.2 mm |

| M6 | 1.0 mm | 10.0 mm | 5.0 mm | 1.6 mm |

| M8 | 1.25 mm | 13.0 mm | 6.0 mm | 2.0 mm |

| M10 | 1.5 mm | 16.0 mm | 8.0 mm | 2.5 mm |

Key Features

The robust Cheese Head design coupled with PVDF material provides a high-performing fastener:

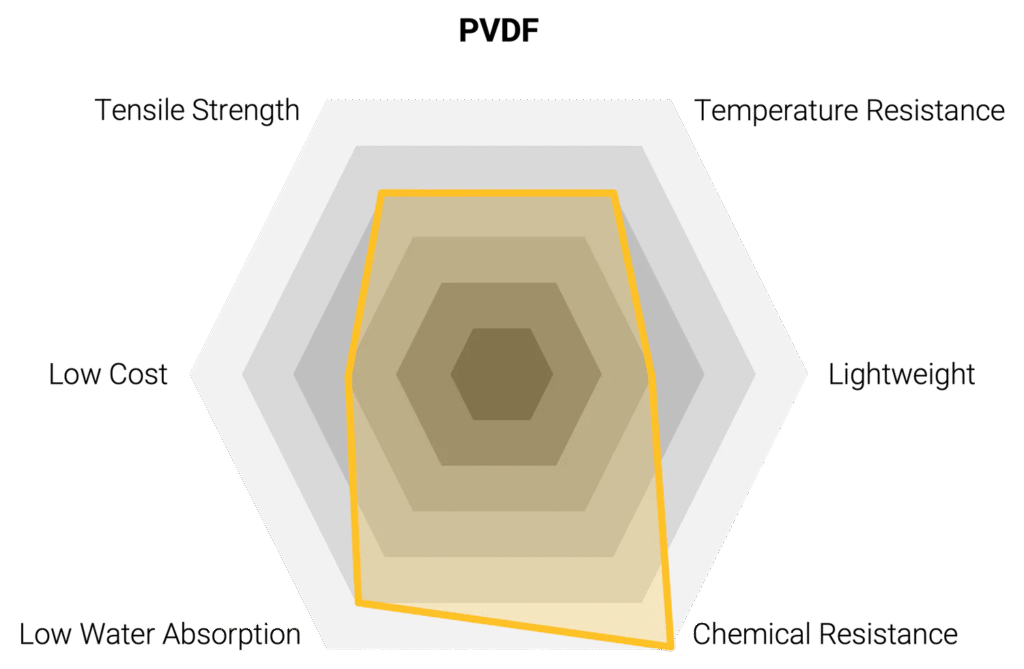

Exceptional Chemical Resistance: Highly inert and resistant to halogens (chlorine), strong acids, and oxidizers, crucial for chemical handling.

Superior UV and Weather Resistance: Maintains properties indefinitely under direct sunlight and outdoor exposure.

High Shear Strength: The robust cylindrical head profile offers excellent resistance to lateral forces for a polymer fastener.

High Purity: Does not leach contaminants, vital for ultrapure water (UPW) systems and sensitive processes.

Good Mechanical Strength: High stiffness and resistance to creep (deformation under sustained load).

Key Polyvinylidene fluoride (PVDF) Properties

Advantages and Disadvantages and Usage Scenarios

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Best-in-class UV, chemical, and purity profile. Robust head geometry provides high shear strength. | High Cost: Significantly more expensive than standard engineering plastics. | Semiconductor Wet Benches: Structural fastening of components in ultrapure water (UPW) and acid bath systems. |

| Design | Robust head ensures maximum material and strength at the bearing surface. Service temperature up to $\approx 150°C. | Slotted Drive Limitation: Provides low torque transmission; easily stripped if over-torqued. | Chemical Processing: Securing internal baffles, mixers, and filters in tanks and vessels exposed to strong oxidizers. |

| Environmental | Long-term outdoor durability. Non-corrosive, non-magnetic, and non-conductive. | Lower Thermal Limit: Max service temperature is lower than PEEK (260°C). | Outdoor Instrumentation: Used in sensors and enclosures exposed to sunlight and aggressive coastal environments. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.