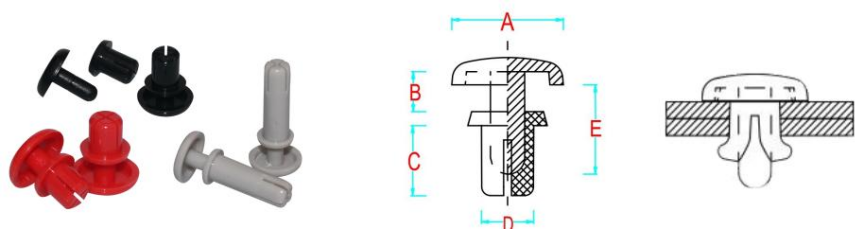

R-type rivet

R-type rivet are single-joint connections suitable for closed or semi-enclosed structures and large-scale production lines requiring rapid assembly.

M Size: R2-R6

peek plastic material: PA66/PP/POM

COLOR:Naturalcolor/pink/blue/orange.Othercolorscanbe Customizable

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

R-type rivet Overview

R-Type Plastic Rivet (often referred to as a Push Rivet, Fir Tree Rivet, or Christmas Tree Rivet) is a lightweight, non-threaded plastic fastener designed for quick, tool-free installation into a pre-drilled hole. Its design relies on resilient, flexible “ribs” or fins that compress upon insertion and then spring back to grip the substrate tightly, locking the rivet into place.

Overview and Design

| Feature | Detail | Purpose |

| Material (Typically Nylon or POM) | Often made from Nylon (Polyamide) for its toughness and resilience, or POM (Acetal) for stiffness and wear resistance. | Ensures the fastener has the necessary elasticity and durability for a secure, long-lasting grip. |

| Design (R-Type/Fir Tree) | Features a cylindrical shank with multiple flexible ribs or fins, and a round or flat head. | The ribs compress when pushed into a hole and then expand behind the substrate to lock the rivet in place, creating a strong pull-out resistance. |

| Application | Permanent or semi-permanent fastening of two or more panels, often dissimilar materials. | Ideal for blind fastening (fastening when only one side of the panel is accessible). |

Product Parameters

R-Type Rivets are characterized by the diameter of the hole they fit into, the length of the shank, and the total thickness of the panels they can join (grip range).

| Designation | Hole Diameter (H) | Head Diameter (D) | Shank Length (L) | Grip Range (G) |

| R3 | 3.0 mm | 6.0 mm | 10 mm | 2.5 mm – 5.0 mm |

| R5 | 5.0 mm | 10.0 mm | 15 mm | 5.0 mm – 8.0 mm |

| R8 | 8.0 mm | 15.0 mm | 20 mm | 7.0 mm – 12.0 mm |

| R10 | 18.0 mm | 25.0 mm | 25 mm | 10.0 mm – 15.0 mm |

Key Features

The popularity of R-Type rivets stems from their ease of use combined with their material advantages:

Speed of Installation: Requires no tools other than a pre-drilled hole; installation is done with a simple push.

Vibration Resistance: The ribbed design provides a snug, tight fit, which offers excellent resistance to loosening under vibration.

Corrosion Immunity: Being made of plastic, they are immune to rust and galvanic corrosion, preventing damage between dissimilar metal panels.

Electrical Insulation: Provides natural electrical isolation between joined panels.

Tolerance Absorption: The flexible ribs can compensate for slight variations or misalignments in the hole size or panel thickness.

Applications

R-Type Rivets are critical in industries focused on fast assembly and material protection:

Automotive: Securing plastic trim, wheel well liners, bumper fascias, and interior acoustic panels to the vehicle body.

Electronics and Appliances: Fastening circuit boards, internal cables, wiring harnesses, and cover panels to metal chassis.

HVAC and Insulation: Securing insulation material to sheet metal ducts and housings.

General Manufacturing: Fastening lightweight panels, signs, and labels to equipment casings.

Advantages

| Category | Advantage (Pro) | Disadvantage (Con) |

| Installation | Extremely fast, tool-free installation. Ideal for automated assembly lines. | Difficult to Remove: Often requires destruction of the rivet for disassembly. |

| Performance | Excellent vibration resistance and high pull-out force. Non-corrosive and non-conductive. | Low Shear Strength: Not suitable for joints subjected to high lateral (shear) forces. |

| Cost | Very economical for mass production and high-volume fastening. | Limited Grip Range: Must select the exact shank length and grip range for the specific panel thickness. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.