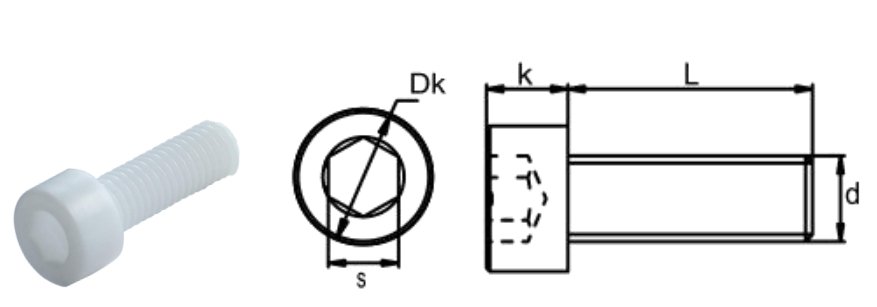

ZrO2 Hexagon socket head screw

ZrO2 Hexagon socket head screw are corrosion-resistant, wear-resistant, high-temperature-resistant, insulating, non-magnetic, and high-purity.

M Size: M4-M12

peek plastic material: Zirconia ceramic fasteners

product Type: Hexagon socket head bolt

Finish: Natural/Black/Other Colors(Customizable)

Search

Product Material

- Chlorinated Polyvinyl Chloride Series(CPVC) (7)

- Perfluoro Alkoxyalkane (PFA) (8)

- Polyamide Nylon (PA66) (19)

- Polycarbonate (PC/PE/POM) (7)

- Polyether Ether Ketone (PEEK) (13)

- Polyphenylene Sulphide (PPS) (9)

- Polypropylene (PP) (10)

- PolytetraFluoroethylene(PTFE) (12)

- Polyvinyl Chloride (PVC) (7)

- Polyvinylidene Fluoride (PVDF) (9)

- RENY MXD6 (50% Glass Fibre Reinforced Nylon) (11)

Product type

Get A Quote

ZrO2 Hexagon socket head screw Overview

ZrO2 (Zirconium Dioxide, or Zirconia Ceramic) Hexagon Socket Head Screw is an ultra-high-performance ceramic fastener. It is primarily selected for its extreme hardness, exceptional mechanical strength, superior wear resistance, and high-temperature stability. The Hexagon Socket drive allows for controlled, concentrated torque application, maximizing the assembly strength achievable with this advanced material. ZrO2 is non-metallic and non-magnetic, making these screws indispensable in environments where the combination of high mechanical load, high heat, and chemical inertness is critical.

I. Overview and Design

| Feature | Detail | Purpose |

| Material (ZrO2 Ceramic) | Zirconium Dioxide (Yttria-Stabilized Zirconia, Y-TZP). A structural ceramic known for its highest toughness among advanced ceramics (due to transformation toughening). | Provides a fastener immune to corrosion and wear, offering high strength comparable to steel in compression, and ultra-high thermal stability. |

| Head Style (Cylindrical Socket Head) | A tall, cylindrical head with a flat top. | Provides a large material volume for high shear strength and allows for installation in tight spaces where external wrench access is limited. |

| Drive Style (Hexagon Socket) | The Allen drive recess. | Allows for the most secure and controlled installation torque achievable with ceramic fasteners, crucial for safe use. |

ZrO2

Product Parameters

ZrO2 Hexagon Socket Head Screws typically follow established metric standards for socket head cap screws, such as ISO 4762 (equivalent to DIN 912).

| Nominal Diameter (d) | Thread Pitch (P) | Head Diameter (D) | Head Height (K) | Socket Size (S) |

| M4 | 0.7 mm | 7.0 mm | 4.0 mm | 3.0 mm |

| M5 | 0.8 mm | 8.5 mm | 5.0 mm | 4.0 mm |

| M6 | 1.0 mm | 10.0 mm | 6.0 mm | 5.0 mm |

| M8 | 1.25 mm | 13.0 mm | 8.0 mm | 6.0 mm |

| M10 | 1.5 mm | 16.0 mm | 10.0 mm | 8.0 mm |

| M12 | 1.75 mm | 18.0 mm | 12.0 mm | 10.0 mm |

Key Features

ZrO2 offers a unique combination of ceramic properties, enhanced by its renowned toughness:

Extreme Hardness & Wear Resistance: Maintains performance in highly abrasive, sliding, or erosive environments at high speeds.

Highest Toughness (among ceramics): Superior resistance to crack propagation compared to (Alumina), reducing the risk of catastrophic failure.

Ultra-High Temperature Stability: Maintains mechanical strength and dimensional stability at temperatures well above 1000°C.

Chemical Inertness: Almost completely immune to corrosion from acids, alkalis, molten salts, and strong chemicals.

Non-Conductive & Non-Magnetic: Essential for electrical insulation and use in sensitive magnetic fields (e.g., MRI).

Advantages and Disadvantages and Usage Scenarios

| Category | Advantage (Pro) | Disadvantage (Con) | Usage Scenarios |

| Performance | Extreme toughness and strength (highest of all ceramics). Exceptional wear resistance and dimensional stability. | Very High Cost: Expensive due to specialized material processing (sintering, grinding). | High-Wear Machinery: Fastening components in pumps, valves, or tooling subject to extreme friction and erosion. |

| Material | Ultra-high thermal stability and complete chemical inertness. Non-conductive and non-magnetic. | Brittleness: Despite its toughness, it is still brittle compared to metal; susceptible to failure from excessive impact or sudden thermal shock. | Semiconductor/High-Purity: Securing parts in plasma etching chambers and systems requiring zero contamination. |

| Design | Socket head allows for high, controlled torque and enables compact, recessed assembly. | Installation Risk: Requires precise, low-impact torque tools to avoid stress-induced micro-cracking during installation. | Vacuum Systems/Aerospace: Fastening in high-vacuum or ultra-high temperature environments where outgassing and thermal stability are crucial. |

Packaging & Delivery

Standard packaging includes PE bag, foam cover, and one double-deck corrugated outer carton for safety during transit. Delivery time is 5-15 working days depending on the quantity.